TM-9-2815-205-34 - Page 37 of 596

TM 9-2815-205-34

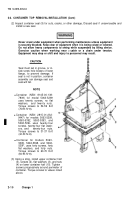

2-3. CONTAINER TOP REMOVAL/lNSTALLATION (Cont)

(2) Inspect container seal (9) for cuts, cracks, or other damage, Discard seal if unserviceable and

install a new seal.

Never crawl under equipment when performing maintenance unless equipment

is securely blocked. Keep clear of equipment when it is being raised or lowered.

Do not allow heavy components to swing while suspended by lifting device.

Exercise caution when working near

a

cable or a chain under tension.

Equipment may drop or shift and injury to personnel may result.

CAUTION

Seal must set in groove, or in-

side screw hole bosses of lower

flange, to prevent damage. If

seal is not in position, container

assembly can damage seal and

seal will fail.

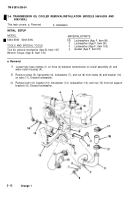

NOTE

●

Container (NSN 8145-00-138-

7809) for model 5063-5299

uses twenty screws, no flat

washers,

and twenty nuts,

Torque screws to 54-59 Ib-ft

(76-83 N•m),

●

Container (NSN 2815-01-232-

9447) for models 5063-5299,

5063-5392, 5063-5393, and

5063-539L uses twenty-four

screws, twenty-four flat wash-

ers, and

twenty-four nuts.

Torque screws to 31-37 Ib-ft

(42-50 N•m).

●

Container for models 5063-

5395, 5063-5398, and 5063-

539F, uses forty screws, forty

flat washers, and forty nuts.

Torque screws to 60-70 Ib-ft

(84-95 N•m),

(3) Using a sling, install upper container half

(5), screws (2), flat washers (3), and nuts

(4) on lower container half (10). Tighten

screws progressively around perimeter of

container. Torque screws to values noted

above.

2-10

Change 1

Back to Top