TM-9-2815-205-34 - Page 394 of 596

TM 9-2815-205-34

3-57. ENGINE/TRANSMISSION OIL COOLER REPAIR (MODEL 5063-5392) (Cont)

(b)

(c)

(d)

(e)

Immerse oil coolers in solution.

Watch cleaning process carefully. Remove oil coolers from solution when bubbling stops

(usually 30 to 60 seconds).

Flush oil coolers in clean hot water.

After cleaning oil cooler, dip in light oil.

•

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles

and gloves and use in a well-ventilated area. Avoid contact with skin, eyes, and

clothes. Do not breathe vapors. Do not use near open flame or excessive heat.

The flash point is 100-138°F (38-50°C). if you become dizzy while using cleaning

solvent, get fresh air immediately and seek medical aid. If contact with eyes is

made, wash with water and get medical aid immediately.

•

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

(3) Clean oil cooler housing and cover with cleaning solvent and dry with compressed air.

c. Pressure check

WARNING

Protect personnel against any stream of pressurized water from a leak or rupture

of a fitting, hose, or oil cooler during high-pressure air-leak test.

(1)

(2)

(3)

(4)

3-264

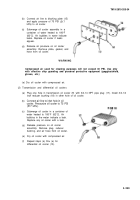

Install rubber gasket (11), fabricated

blocking plate (12), ten 5/16

inch-diameter screws, flat washers, and

nuts on transmission oil cooler (7) or

engine oil cooler (13).

Connect air line to blocking plate (12) and

apply pressure of 75 PSI (517 kPa) to oil

cooler.

Submerge oil cooler assembly in a

container of water heated to 180°F

(82°C). Air bubbles in water indicate

leaks. Replace oil cooler if leaks appear.

Release air pressure on cooler assembly.

Remove blocking plate, rubber gasket,

and hose from oil cooler.

WARNING

Back to Top