TM-9-2815-205-34 - Page 398 of 596

TM 9-2815-205-34

3-58. ENGINE/TRANSMISSION OIL COOLER REPAIR (MODELS 5063-5393, AND 5063-539L)

(Cont)

(b)

(c)

(d)

(e)

Immerse oil cooler in solution.

Watch cleaning process carefully. Remove oil cooler from solution when bubbling stops

(usually takes 30 to 60 seconds).

Flush oil cooler in clean hot water.

After cleaning oil cooler, dip in light oil.

(3) Transmission oil cooler - water side

Coolant system cleaning solution is an acid. Wear protective goggles and

equipment. Avoid contact with skin, eyes, and clothing. If contact is made, flush

area with water and seek medical aid immediately or injury may result.

CAUTION

Coolant system cleaning solution is an acid. Neutralize solution residue or it may

corrode tubes in oil cooler.

(a) Circulate cleaning solution through tubes.

(b) Run a bore brush through tubes in oil cooler.

(c) Rinse tubes with clean, hot water.

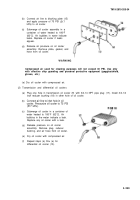

(4) Transmission oil cooler - oil side

(a)

Position oil cooler in a vertical

position. Ensure oil cooler is

adequately supported for cleaning

operation.

CAUTION

Do not use 1 1/4 NPT reducer

bushing. Oil cooler port is notta-

pered and damage will result,

NOT E

Minimum seepage past the

reducer bushing is acceptable

during cleaning procedure.

(b)

(c)

3-268

Install fabricated reducer bushing (15) from transmission oil cooler pressure test kit in

bottom port of oil cooler (9).

Connect air line to fabricated reducer bushing (15).

Change 1

Back to Top