TM-9-2815-205-34 - Page 404 of 596

TM 9-2815-205-34

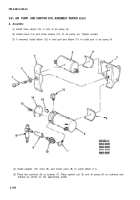

3-59. ENGINE OIL COOLER REPAIR (MODELS 5063-5395, 5063-5396, AND 5063-539F) (Cont)

c. Pressure check

WARNING

Protect personnel against any stream of pressurized water from a leak or rupture

of a fitting, hose, or oil cooler when making this pressure test.

(1)

(2)

(3)

(4)

Install a rubber gasket (9), fabricated blocking plate (10), eight 5/16 inch-diameter bolts, flat

washers, and nuts on flanged side of oil cooler (11) with air line connection at inlet opening in

oil cooler.

Connect air line to steel plate (10) and apply pressure of 75 PSI (517 kPa) to oil cooler.

Submerge oil cooler assembly in a container of water heated to 180°F (82°C). Air bubbles in

the water indicate leaks. Replace oil cooler if it leaks.

Release air pressure on cooler assembly. Remove plate, gasket, and hose from oil cooler.

WARNING

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

(5) Dry oil cooler with compressed air.

3-274

Back to Top