TM-9-2815-205-34 - Page 406 of 596

TM 9-2815-205-34

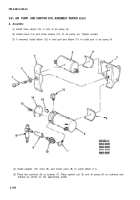

3-60. OIL FILTER ADAPTOR REPAIR

This task covers: a. Disassembly

b. Cleaning/Inspection

c. Assembly

lNITIAL SETUP

MODELS

EXPENDABLE/DURABLE SUPPLIES

All

Oil, fuel (App C, Item 27)

TOOLS AND SPECIAL TOOLS

Tool kit, general mechanics (App B, Item 107)

Tester, spring (App B, Item 103)

a. Disassembly

WARNING

Spring is under compression. Wear eye protection and use care when removing

spring. injury to personnel may result from possible airborne parts.

Remove screw (1), retainer (2), spring (3), and bypass valve (4) from adapter (5).

b. Cleaning/Inspection

c.

WARNING

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

(1) Clean parts with fuel oil and dry with compressed air.

(2) Inspect all parts for damage and excessive wear and replace as necessary.

(3) Using a spring tester, check bypass spring (3) load. At 1.02 inches, minimum compression

load must be 13.5 pounds. Replace as necessary.

Assembly

Install bypass valve (4), spring (3), retainer (2), and screw (1) in adapter (5). Tighten screw

securely.

3-276

Back to Top