TM-9-2815-205-34 - Page 415 of 596

(1)

(2)

(3)

Do not wash bearing assembly. Fuel oil or cleaning solvent will dissolve internal grease

and destroy bearing assembly.

Wash pulley and bracket in cleaning solvent and dry with compressed air.

Inspect pulley and bracket for excessive wear or cracks.

Revolve shaft in bearing assembly by

hand. If rough or tight spots are detected,

replace bearing assembly.

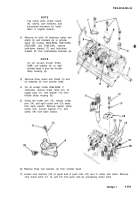

c. Assembly

(1)

(2)

NOT E

Bearing assembly (2) will fit in

pulley from either side; how-

ever, position bearing assem-

bly on pulley as shown for

proper installation.

Support pulley (3) and press bearing

assembly (2) on pulley with shaft

extended upward. Using 1 1/4 inch-

diameter sleeve (8), press outer race of

bearing until flush with inside surface of

pulley.

CAUTION

Do not press bearing shaft (1)

into bearing assembly (2).

Pressure on shaft will distort

bearings and destroy bearing

assembly.

NOT E

Pulley and bearing assembly

will fit in bracket from either

side; however, position pulley

and bearing assembly on

bracket as shown.

Support bracket (6) and press bearing

and pulley assembly (9) into bracket

using 1/2 inch-diameter shaft (7). Apply

pressure to shaft (1) only. Measure

distance (A) between outer edge of pulley

and bracket using thickness gage.

Distance must be 0.160 inch (0.406 cm).

END OF TASK

3-285

TM 9-2815-205-34

CAUTION

Back to Top