TM-9-2815-210-34-2-2 - Page 20 of 968

TM 9-2815-210-34-2-2

CHAPTER 4

CLEANING, INSPECTION, AND REPAIR

Section I. SCOPE

4-1. EQUIPMENT ITEMS COVERED.

This chapter gives instructions for cleaning,

inspection, and repair of engine accessories and engine components.

4-2. EQUIPMENT ITEMS NOT COVERED.

All equipment items are covered in this

Section II.

GENERAL CLEANING,

TOOLS:

No special tools required

INSPECTION, AND REPAIR

SUPPLIES:

Solvent, dry cleaning, type II (SD-2), Fed. Spec

Compressed air source, 30 psi max

Stiff wire

Penetrant kit, MIL-I-25135

PERSONNEL: One

EQUIPMENT CONDITION: Engine disassembled.

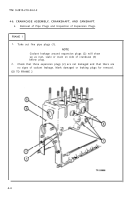

4-3. CLEANING.

PROCEDURES

P-D-680

a.

Clean all parts before inspection, after repair, and before assembly.

b .

Clean all bearing cones and cups. Refer to Inspection, Care,

ante of Antifriction Bearings, TM 9-214.

WARNING

Dry cleaning solvent is flammable. Do not use

near an open flame.

Keep a fire extinguisher

nearby when solvent is used. Use only in well-

ventilated places.

Failure to do this may result

in injury to personnel and damage to equipment.

Do not use more than 30 psi of

air

pressure for

drying parts.

Eye shields must be worn when

using compressed air. Eye injury can occur

if eye shields are not used.

CAUTION

When scraping gasket material from surface of

parts, be careful not to scratch or gouge metal

surfaces.

c .

Clean all other parts with solvent. Scrape all gasket material

of parts.

Rinse parts in clean solvent and dry with compressed air.

and Mainten-

from surface

4-1

Back to Top