TM-9-2815-225-34-P - Page 258 of 736

TM 9-2815-225-34&P

0026 00

0026 00-6

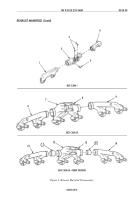

TURBOCHARGER (Contd)

ASSEMBLY

1.

Apply OE/HDO 30 lubricating oil to new bearing (16) and install in bearing housing (17).

2.

Bend edges of new bearing insert pad (15) over bearing housing (17). Apply OE/HDO 30

lubricating oil to bearing insert pad (15) and install on bearing (16).

3.

Apply OE/HDO 30 lubricating oil to new ring seal (12) and install on new sleeve (11).

4.

Install new sleeve (11) and ring seal (12), with spiral grooves facing bearing, in new diffuser

plate (13) until sleeve is flush with turbocharger impeller (1) end.

5.

Apply OE/HDO 30 lubricating oil to new O-ring (14) and install on diffuser plate (13).

CAUTION

Do not rotate diffuser plate after assembly. Any rotation will

displace and damage bearing insert pad.

NOTE

Ensure bearing insert pad is centered during diffuser plate

installation.

6.

Install diffuser plate (13) on bearing housing (17).

7.

Position new insulated packing (19) on bearing housing (17), with flat side of insulated

packing (19) facing out.

8.

Align heat shield (20) locating tabs with depressions in bearing housing (17) and install heat

shield (20) on bearing housing (17).

NOTE

New seals must be expanded slightly before installation. Do

not overexpand seals or an improper fit on wheel and shaft

may occur.

9.

Install two new seals (21) on wheel and shaft (22). Rotate seal gaps 90º apart.

WARNING

Turbine wheel machined edges are very sharp. Wear

protective gloves when handling turbine wheel. Failure to do

so may result in injury to personnel.

10.

Install wheel and shaft (22) in bearing housing (17). Ensure heat shield (20) and sleeve (11)

remain in position.

11.

Using press, install turbocharger impeller (1) on wheel and shaft (22).

12.

Install new impeller locknut (2) on wheel and shaft (22). Tighten locknut (2) 20–24 lb-ft

(27–32 N

•

m).

13.

Apply antiseize compound to turbine housing (23). Align mark (7) made on turbine housing (23)

to mark (7) on bearing housing (17). Install turbine housing (23) on bearing housing (17).

14.

Apply antiseize compound on impeller housing (6). Align mark (7) made on impeller housing (6)

to mark (7) on bearing housing (17). Install impeller housing (6) on bearing housing (17).

15.

Install V-band clamp (5) on impeller housing (6), bearing housing (17), and turbine housing (23)

with two new screws (9), four washers (3) and (8), and two new locknuts (4). Tighten locknuts (4)

58–68 lb-in. (6.6–7.7 N

•

m).

16.

Apply antiseize compound to two adapters (10) and (18) and install on bearing housing (17).

Tighten adapter (10) 20–25 lb-ft (27–34 N

•

m). Tighten adapter (18) 50 lb-ft (68 N

•

m).

17.

Using feeler gauge, measure clearance between turbine housing (23) and V-band clamp (5).

Minimum clearance is 0.035 in. (0.889 mm). Loosen V-band clamp (5) and adjust turbine housing

(23) as necessary to obtain correct clearance.

18.

Using feeler gauge, measure clearance between impeller (1) and inside of impeller housing (6).

Minimum clearance is 0.006–0.025 in. (0.152–0.635 mm). Loosen V-band clamp (5) and adjust

impeller housing (6) as necessary to obtain correct clearance.

Back to Top