TM-9-2815-225-34-P - Page 368 of 736

TM 9-2815-225-34&P

0042 00

0042 00-14

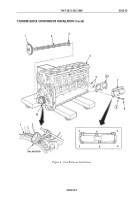

CYLINDER BLOCK COMPONENTS INSTALLATION (Contd)

ACCESSORY DRIVE PULLEY

NOTE

Remove pipe plug from front gear cover and ensure timing

marks on camshaft gear and accessory drive gear are aligned.

Reinstall pipe plug in front gear cover and torque to 35–45 lb-ft

(48–61 N

•

m).

1.

Apply high pressure lubricant to accessory driveshaft (7).

NOTE

Ensure short leg of keyway seal faces toward inside of

accessory drive shaft.

2.

Install new keyway seal (5) on accessory driveshaft (7).

NOTE

Perform steps 3 through 5 for Big Cam I engines only.

3.

Align accessory drive pulley (4) keyway with dowel pin (8) on accessory driveshaft (7).

4.

Using pulley installation tool, install accessory drive pulley (4) on accessory driveshaft (7).

5.

Align keyway seal (5) on keyway of accessory drive pulley (4). Ensure short leg of keyway seal (5)

faces toward inside of accessory driveshaft (7) and washer (3) or it will crush against L of seal (5).

NOTE

Perform steps 6 through 8 for Big Cam III only.

6.

Align accessory drive pulley (6) keyway with dowel pin (8) on accessory driveshaft (7).

7.

Align new keyway seal (5) on keyway of accessory drive pulley (6). Ensure short leg of keyway seal

(5) faces toward inside of accessory driveshaft (7) and washer (3) or it will crush against L of

seal (5).

NOTE

Hold crankshaft at flywheel end when applying torque.

8.

Install new locknut (2) and washer (3) on accessory driveshaft (7). Tighten locknut (2) 300–310

lb-ft (407–420 N

•

m).

NOTE

Perform step 9 for Big Cam III only.

9.

Position accessory drive pulley assembly (4) on accessory drive pulley (6) with six bolts (1).

Tighten bolts 40–45 lb-ft (54–61 N

•

m).

Back to Top