TM-9-2815-225-34-P - Page 397 of 736

TM 9-2815-225-34&P

0044 00

0044 00-3

FUEL PUMP TESTING AND CALIBRATION (Contd)

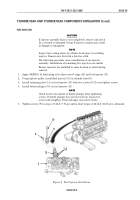

HIGH-SPEED ADJUSTMENT

1.

Remove spring pack cover (9), three captive washer screws (6), screw (8), and four washers (5)

from fuel pump (3).

2.

Remove fuel pump gasket (10) from fuel pump (3). Discard gasket (10).

3.

Remove snapring (11) from fuel pump (3). Discard snapring (11).

4.

Remove spring retainer (12) from fuel pump (3).

NOTE

Each 0.0001 in. (0.025 mm) shim thickness will change speed

approximately 2 rpm.

5.

Add or remove shims (13) behind spring (14). High-speed adjustment should be 2130 to 2150 rpm.

6.

Install spring retainer (12) and new snapring (11) on guide (15).

7.

Install spring pack cover (9) and new gasket (10) on fuel pump (3) with three captive washer

screws (6), screw (8), and four washers (5). Tighten screws (6) and (8) 9–11 lb-ft (12–15 N

•

m).

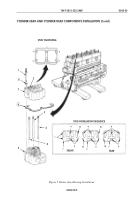

NOTE

Do not use this check to make governor speed adjustments. If

no-load speed is much greater than specifications, examine

governor for malfunction or faulty parts.

8.

Operate engine (1) to purge air from fuel system and bring up to operating temperature.

9.

Bring engine (1) to full throttle and hold. Note maximum rpm. Speed should be 10–12 percent

greater than governor speed cutoff point.

Figure 1. Idle Speed Adjustment.

3

1

2

4

15

16

12

5

6

7

8

5

9

10

11

13

14

Back to Top