TM-9-2815-225-34-P - Page 390 of 736

TM 9-2815-225-34&P

0043 00

0043 00-6

CYLINDER HEAD AND CYLINDER HEAD COMPONENTS INSTALLATION (Contd)

ROCKER ARM HOUSING (Contd)

NOTE

Engine cylinders are numbered in sequence, starting at front

with No. 1 cylinder. The engine firing order is 1-5-3-6-2-4.

Valves and injectors for the same cylinder are not adjusted at

same index mark on accessory drive pulley. One pair of valves

from one cylinder and one injector on a different cylinder are

adjusted at each pulley index mark before rotating accessory

drive to next index mark.

Two crankshaft revolutions are required to adjust all valves

and injectors.

8.

Using medium grit emery cloth, remove paint on timing marks (2), (3), and (4) on accessory drive

pulley (1).

9.

Rotate accessory drive pulley (1) clockwise until line in front of timing mark (2) aligns with

pointer (6) on front gear cover (5).

NOTE

Steps 10 through 16 covers adjustment for cylinder No. 3.

10.

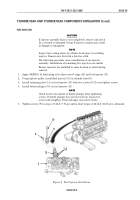

Loosen adjusting screw nut (8) several turns.

11.

Tighten adjusting screw (9) until all clearance is removed between rocker lever (10) and injector

detent plunger.

12.

Tighten adjusting screw (9) one additional turn.

13.

Loosen adjusting screw (9) one complete turn until spring washer inside injector is against stop of

injector.

14.

Tighten adjusting screw (9) 5–6 lb-in (0.6–0.7 N

•

m).

15.

Repeat step 14 several times to make certain adjusting screw (9) is correctly tightened.

NOTE

If torque driver ST-669 is used, tighten adjusting screw nut

35 lb-ft (48 N

•

m).

16.

Prevent adjusting screw (9) from turning and tighten adjusting screw nut (8) 45 lb-ft (61 N

•

m).

NOTE

Adjustment for intake valve is similar to exhaust valve except

for valve clearance difference.

Steps 17 through 20 covers intake and exhaust valve

adjustment for cylinder No. 5.

17.

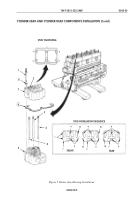

Loosen adjusting screw nut (8).

NOTE

Cold valve clearance for exhaust valve is 0.023 in. (0.584 mm)

and valve clearance for intake valve is 0.011 in. (0.279 mm).

18.

Place feeler gauge between rocker lever (10) and crosshead (11).

19.

Slowly tighten screw (9) until rocker lever (10) touches feeler gauge.

Back to Top