TM-9-2815-225-34-P - Page 392 of 736

TM 9-2815-225-34&P

0043 00

0043 00-8

CYLINDER HEAD AND CYLINDER HEAD COMPONENTS INSTALLATION (Contd)

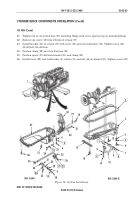

ENGINE BRAKE RETARDER

NOTE

The following procedure covers installation of one engine brake

retarder. Installation of remaining engine brake retarders are

similar.

1.

Install new gasket (11) on rocker arm housing (13).

2.

Install engine brake retarder (3) on two rocker arm housing studs (14).

3.

Install fan bracket (1) and two spacers (5) on two rocker housing studs (14).

4.

Install six nuts (2) on rocker housing studs (14). Tighten nuts (2) 60 lb-ft (81 N

•

m) in sequence

shown in figure 4.

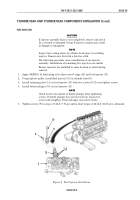

NOTE

The following procedure covers adjustment for one slave piston.

There are two slave pistons per brake retarder, or one per

cylinder. The adjustment for the remaining five slave pistons is

similar. Ensure locknuts are loose before adjusting setscrew.

The adjustment procedure for slave piston requires engine

crankshaft to be rotated and accessory drive pulley assembly

positioned on timing mark A, B, or C. When positioned at

timing mark A, cylinders No. 5 or 2 can be adjusted. When

positioned at timing mark B, cylinders No. 3 or 4 can be

adjusted. When positioned at timing mark C, cylinders No. 6 or

1 can be adjusted.

5.

Loosen locknut (8) and setscrew (9) until there is no pressure or tension.

6.

Using feeler gauge, check slave piston (12) clearance between slave piston (12) and crosshead (4).

Adjust clearance to 0.018 in. (0.457 mm).

CAUTION

After slave piston adjusting screw locknut has been tightened

to specified value, check clearance with feeler gauge again. Do

not overtighten adjusting screw locknut or clearance may

change and result in damage to engine.

7.

Tighten locknut (8) 40 lb-ft (54 N

•

m).

8.

Using feeler gauge, recheck slave piston (12) clearance.

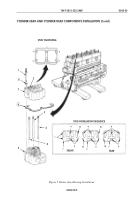

9.

Connect spade end of solenoid harness (7) to solenoid valve (6).

10.

Connect receiver end of solenoid harness (7) to terminal (10) inside engine brake retarder (3).

Back to Top