TM-9-2815-225-34-P - Page 398 of 736

TM 9-2815-225-34&P

0044 00

0044 00-4

FUEL PUMP TESTING AND CALIBRATION (Contd)

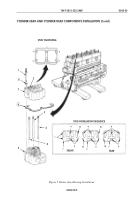

CHECKING AND ADJUSTING FUEL RAIL

NOTE

It should not be necessary to adjust fuel rail pressure on a

newly calibrated fuel pump more than +/- 2 psi (+/- 14 kPa). If

adjustments greater than this are required, fuel pump test

stand, injector test stand, or engine problems may exist. Do not

remove throttle shaft ball unless fuel rail pressure adjustment

needs to be performed.

The correct method of checking engine fuel rail pressure is with

engine installed on a chassis or engine dynamometer.

1.

Check governor speed cutoff and adjust if necessary.

2.

Install fuel rail pressure gauge (4) between fuel supply elbow (11) on fuel pump assembly (10) and

female union tee (12).

3.

Bring engine (3) to full throttle load until rpm falls to rated speed.

4.

Note fuel rail pressure gauge (4) reading. If pressure is above or below 83 psi, perform steps 5–8.

CAUTION

Do not turn threaded stud out beyond maximum throttle

travel. The fuel hole in the throttle shaft will begin to close.

Never adjust fuel rail pressure above maximum specifications.

This will void engine warranty and violate Environmental

Protection Agency (EPA) requirements.

5.

Turn threaded stud (9) out to obtain maximum throttle travel and secure with jamnut (8).

6.

Remove throttle shaft ball (5) from throttle shaft (6).

NOTE

It should not be necessary to adjust fuel manifold pressure on a

newly calibrated pump more than +/- 2 psi (+/- 14 kPa). If

adjustments greater than these are required, fuel pump test,

injector test stand, or engine problems may exist.

7.

Turn fuel adjusting screw (7) in throttle shaft (6) in to increase or out to decrease pressure while

watching fuel rail pressure gauge (4).

8.

Using throttle shaft ball installing tool (1), install throttle shaft ball (5) into end of throttle shaft

(6).

Back to Top