TM-9-2815-225-34-P - Page 396 of 736

TM 9-2815-225-34&P

0044 00

0044 00-2

FUEL PUMP TESTING AND CALIBRATION (Contd)

WARNING

Allow adequate ventilation for engine exhaust gases. Do not

perform fuel system procedures while smoking or within 50 ft

(15.2 m) of sparks or open flame. Diesel fuel is flammable and

may explode. Failure to comply may result in serious injury or

death to personnel.

PREADJUSTMENT CHECKS

CAUTION

Do not alter pump settings to match gauges and tachometers of

unknown accuracy. Failure to comply may result in damage to

equipment.

NOTE

Vehicle fuel control lever and throttle stop linkage should have

a maximum throttle stop, so when fuel pump full throttle is

obtained, override pressure will not be on throttle shaft.

After proper calibration, fuel pump should require very little

adjustment. Some adjustment may be required at idle, since

this setting is dependent on parasitic loads. Fine adjustment of

governor settings and fuel manifold pressure is permissible

within the limits specified if justified by engine performance

tests.

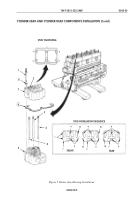

Check and adjust throttle control linkage for full throttle

operation and throttle released operation with the throttle

stopped by the throttle leakage adjusting screw.

IDLE SPEED ADJUSTMENT

NOTE

Idle speed adjustment should never be made on a cold engine.

Engine must be operated for sufficient time to purge all air

from the fuel system and to bring the engine up to operating

temperature (at least 165° F (74° C) oil temperature).

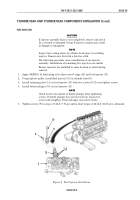

1.

Remove plug (7) from spring pack cover (9) and start engine (1) on dynamometer (2).

NOTE

Fuel pump idle adjusting tool will not let the spring pack cover

leak when the idle is adjusted.

2.

Turn idle adjusting screw (16) in to increase engine rpm, out to decrease rpm.

3.

Using idle adjusting tool (4), set idle to 600 +/- 2 rpm.

4.

Install plug (7) on spring pack cover (9).

Back to Top