TM-9-2815-225-34-P - Page 386 of 736

TM 9-2815-225-34&P

0043 00

0043 00-2

CYLINDER HEAD AND CYLINDER HEAD COMPONENTS INSTALLATION (Contd)

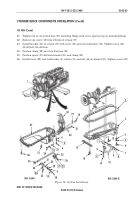

CYLINDER HEAD

NOTE

The following procedure covers installation of one cylinder head

assembly. Installation of remaining cylinder heads is similar.

Perform steps 1 through 10 to install each additional cylinder

head assembly as required.

Ensure marks made on each cylinder head and cylinder block

during removal are matched together during installation so

that each cylinder head assembly is installed in its original

position on cylinder block.

Ensure new cylinder head gasket has the side with word TOP

facing upwards.

1.

Install new cylinder head gasket (7) on cylinder head (5).

2.

Install cylinder head (5) on cylinder block (6).

3.

Apply rust preventative lubricant to twelve screws (4). Allow excess lubricant to drip from screw

threads before installation.

4.

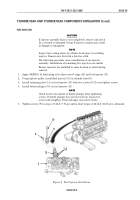

Install twelve screws (4) and washers (3) on cylinder head (5). Tighten screws (4) 25 lb-ft (34 N

•

m)

in sequence shown in figure 1.

5.

Tighten screws (4) 100 lb-ft (136 N

•

m) in sequence shown in figure 1.

NOTE

Perform step 6 for Big Cam I only.

6.

Tighten screws (4) 305 lb-ft (414 N

•

m) in sequence shown in figure 1.

NOTE

Perform step 7 for Big Cam III only.

7.

Tighten screws (4) 285 lb-ft (387 N

•

m) in sequence shown in figure 1.

8.

Apply OE/HDO 10 lubricating oil to four new O-rings (8).

9.

Install O-rings (8) on counterbores of cylinder head (5).

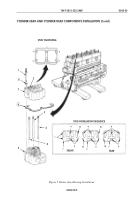

10.

Install two fuel crossover connections (1) on cylinder head (5) with four screws (2). Tighten screws

(2) 38 lb-in (4.3 N

•

m).

Figure 1. Cylinder Head Installation.

TIGHTENING SEQUENCE

6

5

7

8

1

2

3

4

I

L

K

J

F

B

E

H

D

A

C

G

Back to Top