TM-9-2815-225-34-P - Page 432 of 736

TM 9-2815-225-34&P

0047 00

0047 00-8

ENGINE TESTING (Contd)

SMOKE LEVEL CHECK

NOTE

Zero and place opacity meter at exhaust side of turbocharger.

An accurate smoke reading can usually be obtained in 10 to 15

seconds.

1.

Using 0–20 scale on opacity meter, record smoke reading. Specification is 12.84 percent

(3.6 percent Bosch).

2.

Increase dynamometer test stand load until rpm is reduced to 60 percent of rated rpm.

3.

Using 0–20 scale on opacity meter, record smoke reading. Specification is 3.87 percent

(1.0 percent Bosch). Remove meter after reading is taken.

4.

Reduce dynamometer test stand load and engine (3) rpm.

5.

Accelerate engine (3) to rated rpm, no-load and return to idle. Full acceleration should occur in

3–5 seconds.

NOTE

Zero and place opacity meter at exhaust side of turbocharger.

6.

Using 0–100 scale on opacity meter, accelerate engine (3) to rated rpm, no-load and record highest

reading. Specification is 22 percent (4.3 percent Bosch).

7.

Return engine (3) to idle.

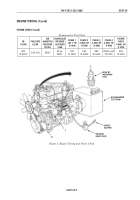

FINAL CHECK

NOTE

If there is no rapid change in excess of 2 in. of water and

reading does not exceed 100 percent of representative pressure,

blow-by is acceptable. Manometer readings not exceeding

0.3 in. (7.62 mm) surge are desirable.

At each phase, record crankcase pressure (blow-by), engine

speed, and load at one minute intervals. Watch for increases or

wide shifts in blow-by pressure. If sudden increase happens, or

if it is more than 12 in. H2O, perform the preceding test over

again and run engine 15 more minutes. If not OK, stop the test

and find reason for too much blow-by. Check engine for fuel,

oil, water, air, or exhaust leaks after each test and fix as

needed.

1.

Using blow-by measuring tool, check pressure at end of testing procedure. If pressure is greater

than specification listed in test chart, run engine (3) for additional 30 minutes at 96–100 percent

rated load and rpm.

2.

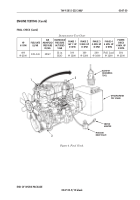

Remove orifice adapter from pressure relief valve.

3.

Remove blow-by measuring tool from engine (3) and install oil filler cap (1) on engine (3).

4.

Unplug breather tube (2).

Back to Top