TM-9-2815-225-34-P - Page 436 of 736

TM 9-2815-225-34&P

0048 00

0048 00-2

BIG CAM III ENGINE INSTALLATION (Contd)

1.

Attach two lifting brackets, lifting sling, and lifting device to engine (4).

WARNING

Use extreme care when handling heavy parts. Provide adequate

support and use assistance during procedure. Ensure that any

lifting device used is in good operating condition and of suitable

load capacity. Keep clear of heavy components supported only

by lifting device. Failure to comply may result in death or

injury to personnel.

Use pry bars to free engine hangups or snags. Do not use

hands. Failure to comply may result in injury to personnel.

NOTE

Use drift pin to aid in alignment of the engine to the

transmission.

2.

Using lifting device and lifting sling, lower engine (4) on frame (1). Ensure that engine and

transmission are properly aligned and there is proper clearance between frame (1) and alternator

(11) and between frame (1) and power steering pump (5).

3.

Install transmission (12) to flywheel housing (21) with twelve bolts (13). Tighten bolts (13) 16 lb-ft

(21 N

•

m).

4.

Install engine brackets (3) on frame (1) with four bolts (2), washers (15), insulators (16), and

nuts (14). Tighten nuts (14) 130–166 lb-ft (176–225 N

•

m).

5.

Install front engine crossmember mount (8) on frame (1) with two bolts (9), four washers (6), two

insulators (7), and nuts (10). Tighten nuts (10) 130–166 lb-ft (176–225 N

•

m).

6.

Remove lifting sling and lifting device from engine lifting brackets (18) and remove transmission

jack from transmission (12).

NOTE

Rotate accessory drive pulley nut to gain access to flywheel

bolts.

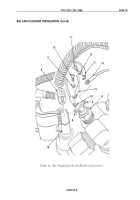

7.

Install flywheel (19) on torque converter (20) with twelve bolts (24) and washers (23). Tighten

bolts (24), 19–21 lb-ft (26–29 N

•

m).

8.

Install P-clamp (17) and flywheel bolt access cover (18) on flywheel housing (21) with two

screws (25).

9.

Connect ether quick-start tube (27) to atomizer (28) on intake manifold (26).

Back to Top