TM-9-2815-225-34-P - Page 426 of 736

TM 9-2815-225-34&P

0047 00

0047 00-2

ENGINE TESTING (Contd)

GENERAL INFORMATION

The engine test is a combination of a run-in procedure and a performance check. The run-in procedure

provides an operating period that allows engine parts to achieve a final finish and fit. The performance

check confirms that the engine will operate at its specified speed and torque rating, that it is leak free,

that it is free of abnormal noises, and that its various systems are operating within specified values.

In the event of conflicting instructions between this procedure and other references, this procedure will

take precedence.

Dynamometer must have sufficient capacity to permit testing at 100 percent of engine’s 400 hp @

2100 rpm.

PRE-TEST INSPECTION

The engine will be inspected for completeness and obvious damage before testing/performance check

(no missing accessories, drive belts installed properly, no missing screws or nuts, etc.).

INSTALLATION OF ENGINE ON DYNAMOMETER

1.

Mount engine (4) on dynamometer test stand following manufacturer’s instructions.

2.

Cover, or plug, breather tube (2).

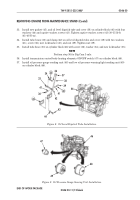

NOTE

Using blow-by measuring tool and water manometer, fill to 0

mark at middle of scale. Close all other engine openings that

would allow blow-by pressure to escape.

3.

Install blow-by measuring tool in place of oil filler cap (1).

4.

Connect air compressor (3) to a 0.125–0.130 in. (3.175–3.302 mm) diameter orifice adapter located

downstream from a 150 psi (1034 kPa) pressure relief valve.

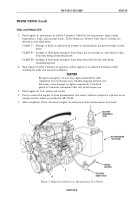

CONDITIONS FOR TESTING

CAUTION

Failure to comply with the following could result in damage to

equipment.

1.

Do not run engine (4) with less than 35 psi (241 kPa) of oil pressure.

2.

Engine oil pressure must not exceed 90 psi (689.5 kPa) at any time.

3.

Engine oil temperature must not exceed 250° F (121° C) at any time.

4.

Engine coolant temperature must not exceed 210° F (96.0° C) at any time.

5.

Do not run engine (4) under full power/load conditions when oil temperature or coolant

temperature is below 190° F (88° C).

6.

Do not shut down engine (4) following heavy power/load runs without a minimum of a 5-minute

cool-down, no-load run.

Back to Top