TM-9-2815-225-34-P - Page 427 of 736

TM 9-2815-225-34&P

0047 00

0047 00-3

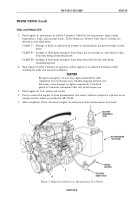

ENGINE TESTING (Contd)

Figure 1. Engine Installation on Dynamometer Test Stand.

FINAL ACCEPTANCE TEST

1.

Start engine (4) and operate at idle for 5 minutes. Check for low oil pressure, high coolant

temperature, leaks, and unusual noises. No fuel leaks are allowed. Only Class I oil leaks are

allowed as described below.

CLASS I— Seepage of fluid (as indicated by wetness or discoloration) not great enough to form

drops.

CLASS II— Leakage of fluid great enough to form drops, but not enough to cause drops to drip

from item being checked/inspected.

CLASS III—Leakage of fluid great enough to form drops that fall from the item being

checked/inspected.

2.

Stop engine (4) after 5 minutes of operation. Allow engine (4) to stand for 2 minutes while

checking for leaks and unusual conditions.

CAUTION

Except in emergency, do not stop engine immediately after

completion of power/torque runs. Sudden stopping without cool-

down may cause damage to engine components. Cool-down

period is 5 minutes (minimum) after any power/torque run.

3.

Start engine (4), test, and record results.

4.

Prior to removal of engine (4) from dynamometer test stand, whether accepted or rejected, an oil

sample must be taken as specified in AR 750-22.

5.

After completion of test, disconnect engine (4) and remove from dynamometer test stand.

3

2

4

1

BLOW-BY

MEASURING

TOOL

DYNAMOMETER

TEST STAND

ORIFICE

ADAPTER

PRESSURE

RELIEF VALVE

Back to Top