TM-9-2910-226-34 - Page 80 of 208

TM 9-2910-226-34

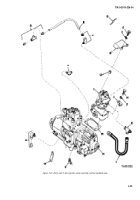

Figure 3-45. Disassembling or assembling timing window cover and fuel shutoff rod assembly.

b. Inspection and Repair.

Inspect and repair

timing window cover and fuel shutoff rod assembly

as follows. Check condition of the rod return spring

(E, fig. 3-45) and replace the spring when it does not

pass visual inspection. Examine the timing window

cover for cracks or distortion. Replace the cover

when cracked or distorted. Examine the gasket

surface of the cover for scratches, nicks, or burs.

Repair minor damage with crocus cloth or a fine mill

file and replace when it is not repairable. Inspect rod

(G) and bearing screw (C) for evidence of wear. Rod

must move freely in screw.

c. Assembly.

Assemble the fuel shutoff rod

assembly and timing window cover as follows. Refer

to figure 3-45.

(1) Install shutoff rod preformed packing (F),

rod return spring (E), and bearing screw (C) on fuel

shutoff rod (G). Compress rod return spring and

position shutoff fitting (B) on fuel shutoff rod and

aline holes in rod and fittings. Drive fitting retaining

pin (A) through holes. Stake fitting retaining pin in

place.

(2) Position shutoff rod gasket (D) on fuel

shutoff rod assembly and install shutoff re

assembly in timing window cover.

3-22. Repair of Fuel Shutoff Solenoid Cover

Assembly (Code A Injection Pumps).

a.

Refer to figure 3-46. Apply 24 v dc to solenoid

electrical connection (A) and ground to housing (F)

to check for solenoid plunger movement. If plunger

(G) does not actuate, replace complete fuel shutoff

solenoid cover assembly. If it does operate, complete

inspection as follows.

b.

Examine the timing window housing portion

(F) for cracks or distortion, and mating surface for

scratches, nicks, or burs. Repair minor damage with

crocus cloth or a fine mill file.

c.

Inspect blackout stop shell (B) for wear or

damage. If worn or damaged, remove sleeve (E), nut

(D), washer (C) and shell (B). Install new shell,

washer, nut, sleeve and repeat step

a

above.

3-34

Back to Top