LO-9-2350-247-12 - Page 35 of 43

LUBRICATION ORDER

LO

9-2350-247-12

8 JULY 1994

(Supersedes LO 9-2350-247-12, March 1982)

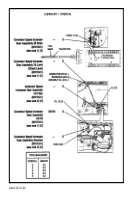

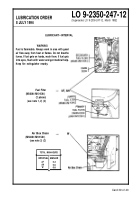

KEY

EXPECTED

REFILL

TEMPERATURES*

LUBRICANTS

CAPACITY

+40°F

0°F

INTERVALS

(APPROX)

Above

to

32°F

to

-10°F

-65°F

OE/HDO (MIL-L-2104C)

LUBRICATING OIL

OE/

OE/

OEA

S - 150 Hours,

OR OEA (MIL-L-46167)

lNTERNAL COMBUSTION

1/4 pt.

HDO-10

HDO-10

1,500 Miles

ENGINE

Winch Transfer

or Semi-annually

Gearcase

CW-11 (VV-L-751)

LUBRICATING OIL

C/MR - Upon

CHAIN-WIRE ROPE,

As Required

CW-11B

CW-11A

GOS

Contamination/

EXPOSED GEAR

During

Maintenance

GO (MIL-L-2105)

LUBRICATING OIL

GEAR, MULTIPURPOSE

Repair

Winch End Frame

0.75 pt.

GO-

GO-

GO-75

Winch Gear Box

2.75 pt.

80/90

80/90

GAA (MIL-G-10924)

GREASE, AUTOMOTIVE

AND ARTILLERY

As Required

All Temperatures

Winch Drive Shaft

For Arctic Operation Refer to FM 9-207

NOTES

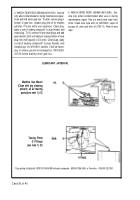

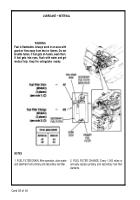

WARNING

threads, and install plug. To fill, remove fill and level plugs

Dry cleaning solvent PD-680 is toxic and flam-

and add oil (OE/HDO) until oil level reaches bottom of

mable. Death or injury may result. Always use in

level plug hole (refill capacity 1/4 pint). Clean plugs, apply

an open area with good air flow, away from sparks,

a coat of sealing compound* to plug threads, and install

heat, or flames. Wear protective goggles and

plugs. During oil change, unscrew gearcase breather

gloves. Do not breathe vapors. Avoid contact with

and clean with dry cleaning solvent (PD-680, type Ill).

Apply a light coat of sealing compound* to breather

skin, eyes, and clothes. If you get dizzy while using

threads and install breather.

solvent, breathe fresh air and get medical help. If

solvent gets on hands, wash them. If solvent gets

2. WINCH END FRAME (M548A1/M1015A1). Service

in eyes, flush eyes with fresh water and get medi-

cal help immediately. Keep fire extinguisher

only when contaminated or during maintenance repair.

Drain and refill winch end frame. To drain, remove plug in

nearby.

bottom of end frame. Inspect plug and oil for metallic

1. WINCH TRANSFER GEARCASE (M548A1/

particles. If found, notify your supervisor. Clean plug,

M1015A1). Every 1,500 miles or semi-annually, drain

apply a coat of sealing compound* to plug threads, and

install plug. To fill, remove fill and level plugs, and add

and refill winch transfer gearcase. To drain, remove drain

gear lubricant (GO) until lubricant reaches bottom of level

pIug in bottom of gearcase housing. Inspect plug and oil

plug hole (refill capacity 3/4 pint). Clean plugs, apply a

for metallic particles. If found, notify your supervisor.

coat of sealing compound* to plug threads, and install

Clean plug, apply a coat of sealing compound* to plug

threads.

Use sealing compound - 8030-00-543-4384 antiseize compound - 8030-00-286-5453, or Permatex - 5330-00-252-3391.

Card 35 of 40

Back to Top