LO-9-2350-247-12 - Page 33 of 43

LUBRICATION ORDER

8 JULY 1994

LO 9-2350-247-12

(Supersedes LO 9-2350-247-12, March 1962)

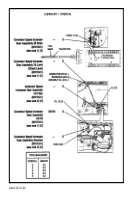

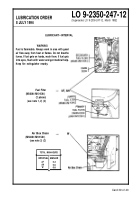

KEY

EXPECTED

REFILL

TEMPERATURES*

LUBRICANTS

CAPACITY

+40°F

0°F

INTERVALS

(APPROX)

Above

32°F

to

to

-10°F

-65°F

OE/HDO (MIL-L-2104C)

LUBRICATING OIL,

4 qt.

OE/

OE/

OEA

D - Daily

OR OEA (MIL-L-46167)

INTERNAL COMBUSTION

HDO-30

HDO-10

ENGINE

S - Every 200 hours

Generator

on generator ETl

Speed Increaser

meter (see TM

9-2350-247-10)

Gear Assembly

or semi-annually

For Arctic Operation Refer to FM 9-207

NOTES

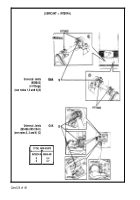

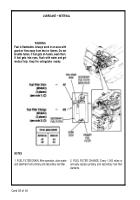

1. GENERATOR SPEED INCREASER GEAR AS-

SEMBLY. Daily check generator speed increaser gear

assembly oil level for between ADD and FULL marks

on gauge rod. Add oil (OE/HDO) through dipstick tube

as necessary. Every 200 hours on generator ETI

meter (TM-2350-247-10) or semi-annually drain

generator speed increaser gear assembly oil. To drain,

remove hull bottom access cover (TM 9-2350-247-20)

and speed increaser drain plug. Inspect oil being

drained for metallic particles. If metal chips are found

in oil, notify your supervisor. Clean and install drain

pIug. Service oil filter and breather (see Notes 2 and 3).

To fill, remove plug with preformed packing and add oil

(OE-HDO) (refill capacity about 4 quarts) to bring level

between ADD and FULL marks on gauge rod. Discard

packing. Clean fill plug, apply coat of antiseize com-

pound to plug threads, position new preformed pack-

mg on Iu and install plug. Run carrier en ine and

check for leaks at filter and at drain plug. INSTALL

BOTTOM ACCESS COVER SECURELY.

WARNING

Dry cleaning solvent PD-680 is toxic and flam-

mable. Death or injury may result. Always use in

an open area with good air flow, away from sparks,

heat, or flames. Wear protective goggles and

gloves. Do not breathe vapors. Avoid contact with

skin, eyes, and clothes. If you get dizzy while using

solvent, breathe fresh air and get medical help.

If

solvent gets on hands, wash them. If solvent gets

in eyes, flush eyes with fresh water and get medi-

cal help immediately. Keep fire extinguisher

nearby.

Use sealing compound – 8030-00-543-4384 antiseize compoun

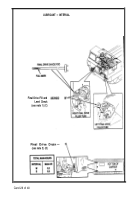

2. GENERATOR SPEED INCREASER GEAR AS-

SEMBLY FILTER. Every 200 hours on generator ETI

meter (TM 9-2350-247-10) or semi-annually

during oil change, replace filter element. Remove

locking wire, cover, filter element, and two preformed

packings (see M1015A1 portion of TM 9-2350-247-

20). Dscard locking wire, element, and packings.

Clean inside of cover with dry cleaning solvent (PD-

680, type III) and install two new packings and new

element. Install filter cover and new locking wire. After

filling generator speed increaser gear assembly (see

Note 1), check for oil leaks with engine operating.

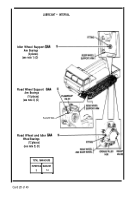

3. GENERATOR SPEED INCREASER GEAR AS-

SEMBLY BREATHER. Every 200 hours on generator

ETI meter (TM 9-2350-247-10) or semi-annually, dur-

ing oil change, clean breather. Remove breather,

clean with dry cleaning solvent (PD-680, type Ill),

apply coat of sealing compound

to breather threads,

and install breather.

NOTE

If M1015A1 carrier has a shelter on it, it may be

necessary (depending on the type of shelter) to

slide shelter back on skid guides for access to

some lubrication points (see M1015A1 portion of

TM 9-2350-247-10.

d - 8030-00-286-5453, or Permalex - 5330-00-252-3391.

Card 33 of 40

Back to Top