LO-9-2350-247-12 - Page 29 of 43

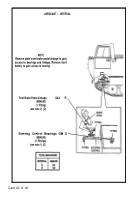

LUBRICATION ORDER

LO 9-2350-247-12

8 JULY 1994

(Supersedes LO 9-2350-247-12, March 1982)

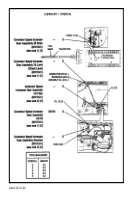

KEY

REFILL

EXPECTED TEMPERATURES*

LUBRICANTS/COMPONENTS

CAPACITY

INTERVALS

(APPROX)

GAA (MIL-G-10924)

GREASE, AUTOMOTIVE

As Required

AND ARTILLERY

Road and Idler

Wheel Bearings

All Temperatures

S - 150 Hours,

Road and Idler

1,500 Miles

Support Arm

or Semi-annually

Bearings

For Arctic Operation Refer to FM 9-207

NOTES

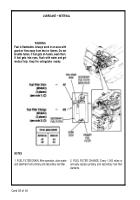

WARNING

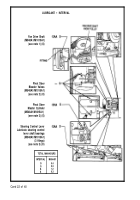

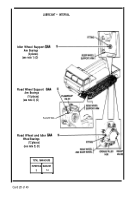

1. IDLER WHEEL SUPPORT ARM BEARINGS.

Dry cleaning solvent PD-680 is toxic and flam-

Every 1,500 miles or semi-annually, lubricate idler

mable. Death or injury may result. Always use in

wheel support arm bearings through fittings as fol-

In open area with good airflow, away from sparks,

lows: use grease gun with grease (GAA) on fitting at

heat, or flames. Wear protective goggles and

rear of support arm until grease appears at relief valve.

gloves. Do not breathe vapors. Avoid contact with

skin,eyes, and clothes. If you get dizzy while using

2. ROAD WHEEL AND IDLER WHEEL BEARINGS.

solvent, breathe fresh air and get medical help. If

Every 1,500 miles or semi-annually, lubricate each

solvent gets on hands, wash them. If solvent gets

road wheel and idler wheel bearings as follows: use

in eyes, flush eyes with fresh water and get medi-

grease (GAA) and grease gun with flexible adapter.

al help immediately. Keep fire extinguisher

Lubricate hub through fitting until grease appears at

nearby.

relief valve.

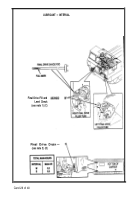

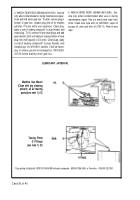

NOTE

Clean grease fittings with dry cleaning solvent

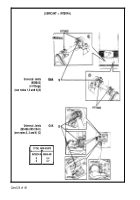

3. ROAD WHEEL SUPPORT ARM BEARINGS.

PD-680, Type Ill, or equivalent) prior to lubrica-

Every 1,500 miles or semi-annually, lubricate all road

tion. Check/lubricate grease fitting points after

wheel support arm bearings. Use grease (GAA) and

washing or fording.

grease gun with flexible adapter on fitting until grease

appears at relief valve. If support arm has plugs but no

When grease fittings will not accept GAA, notify

fittings, remove one plug and install fitting. Remove

unit maintenance.

remaining plug and install relief valve. Perform lubrica-

tion. Remove fitting and relief valve. Clean and install

two plugs.

Card 29 of 40

Back to Top