MWO-5-2350-262-35-3 - Page 9 of 45

MWO 5-2350-262-35-3

2-3

Table 2-1.

MWO Parts List – Continued.

Part No.

CAGE

NSN

Description

Qty

8-4 TRTX-S

30780

Reducer, Tube, -8/-4

1

8338561

19207

Shell

2

8338562

19207

Insulator, Bushing, Sleeve

2

8338564

19207

Terminal

2

900729-3

01276

Clamp, Loop

6

MS21333-104

80502

Clamp, Loop

3

MS3367-1-0

96906

6” Cable Ties

3

12502193

19207

Chain Giude

2

SECTION II

TOOLS REQUIRED

1.

Tool Kit, General Mechanics: Automotive, NSN 5180-00-177-7033.

2.

Shop Equipment, Automotive Maintenance and Repair: Field Maintenance, Basic, Less Power, NSN 4910-00-

754-0705.

3.

Shop Equipment, Automotive Maintenance and Repair: Field Maintenance, Supplemental No.1, Less Power,

NSN 4910-00-754-0706.

4.

Lifting device must have a weight capacity greater than 3865 lb (1753.135 kg).

SECTION III

REMOVAL PROCEDURES FOR TRACK ADJUSTING SYSTEM

1.

Remove apron and dozer assembly per TM 5-2350-262-20-1, Apron and Dozer Assembly Replacement and

Repair.

Remove and inspect steel dozer blade from assembly and if serviceable, retain for future use.

Set aside

remaining parts for disposition per Chapter 1, Section 1-8, step c.

2.

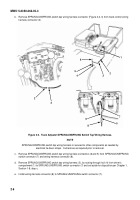

Remove apron wiring harness per TM 5-2350-262-34, Apron Wiring Harness Replacement.

Inspect apron wiring

harness, nut, washer, screw, and pin and if serviceable, retain for future use.

3.

Remove battery box per TM 5-2350-262-20-1, Battery Box Replacement and retain parts for future use.

4.

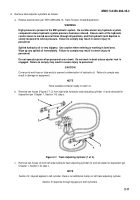

Remove grease track adjusting cylinders, if applicable, per TM 5-2350-262-20-2, Track Adjusting Cylinder

Replacement.

Retain and inspect pin, washers, screw, and locknut from final drive adjusting flange and if

serviceable, retain for future use.

Set aside remaining parts for disposition per Chapter 1, Section 1-8, step c.

Back to Top