TM-5-3805-254-14-P-2 - Page 777 of 894

TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-32 -34

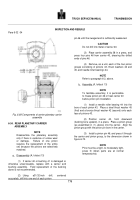

Fig. 6.69 Components of center planetary carrier

assembly

6-34.

REAR PLANETARY CARRIER

ASSEMBLY

NOTE

Disassemble the planetary assembly

only if there is evidence of undue wear

or damage.

Failure of one pinion

requires the replacement of the entire

set, because the pinions are selectively

matched.

a. Disassembly (A, foldout 13)

(1)

If carrier 40 or bushing 41 is damaged or

otherwise unserviceable, replace with a carrier and

bushing assembly.

Field replacement of the bushing

alone is not recommended.

(2)

Using

a31/32-inch

drill,

centered

accurately, drill into one end of each pinion

pin 46 until the swaged end is sufficiently weakened.

CAUTION

Do not drill into metal of carrier 40.

(3)

Place carrier assembly 38 in a press, and

press four pins 46 from carrier 40, shearing the drilled

ends of pins 46.

(4)

Remove, as a unit, each of the four pinion

groups consisting of pinions 43, thrust washers 42 and

45, and needle roller bearings 44.

NOTE

Refer to paragraph 6-2, above.

b. Assembly (A, foldout 13)

NOTE

To facilitate assembly, it is permissible

to freeze pinion pin 46 or heat carrier 40

before pinion pin installation.

(1)

Install a needle roller bearing 44 into the

bore of each pinion 43.

Place a steel thrust washer 45

(first) and a bronze thrust washer 42 (second) onto each

face of pinions 43.

(2)

Position carrier 40, front downward

(bushing bore upward), in a press.

Place a pinion group

(as assembled in (1), above) into the carrier.

Align the

pinion group with the pinion pin bore in the carrier.

(3)

Install a pinion pin 46, and press it through

the carrier and pinion group, to the dimension shown in

figure 6-72.

NOTE

Pins must be a tight, to moderately tight,

press fit (when parts are at normal

temperatures).

770

Back to Top