TM-5-3805-254-14-P-2 - Page 770 of 894

TRUCK SERVICE MANUAL

TRANSMISSION

Para 6-2316-24

HT 700D SERIES TRANSMI SS IONS

(3) Remove oil seal 42 (A, foldout 14) from the

transmission housing.

4) If replacement of breather 1 is necessary, remove

it from the housing.

(5) Inspect neutral safety switch plug 41, washer 40,

and reverse signal plug 4 for damage.

If damaged,

replace with new parts.

(6) If it is necessary to replace nameplate 6, remove

one drive screw 5.

NOTE

All replacement parts ordered refer to the

information both nameplate Therefore it is

imperative that the new nameplate be stamped

with identical information.

NOTE

Refer to paragraph 6-2, above.

b.

Assembly (A, foldout 14)

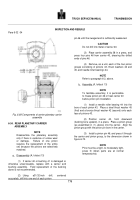

(1) Coat the inside diameter of oil seal 42 (A,

foldout 14) with a seal lubricant, and the outside diameter

with a nonhardening sealant.

Install the oil seal, lip first,

into the transmission housing (Fig. 6-62).

Use installer

32 (Fig. 4-3) to properly locate the seal in the housing.

The seal must clear the chamfer in the housing bore.

(2) Hold detent lever 34 (A, foldout 14) so that the

selector valve pin extends toward the inside of the

housing (Fig. 6-61).Slide the manual shaft through the

opening in the housing, oil seal, and slot in the detent

lever.

Install the locknut and retainer pin. Tighten the

locknut to 15 to 20 pound feet (20 to 27 Nm) torque.

(3) If breather 1 (A, foldout 14) was removed,

install the breather.

(4) If removed, install nameplate 6 and drive screw

5 (refer to a(6), and note, above).

6-24.

LOW PLANETARY CARRIER ASSEMBLY

NOTE

Disassemble the planetary assembly only if

there is evidence of undue wear or damage.

Failure of one pinion requires replacement of

the entire set, because the pinions are

selectively matched.

a.

Disassembly (A, foldout 15) (1) Using a 31/32-inch

drill, centered accurately, drill into one end of each pinion

pin 20 until the swaged end is sufficiently weakened.

CAUTION

Do not drill into metal of carrier 19.

(2) Place carrier assembly 18 in a press, and

press four pins 20 from carrier 19, shearing the drilled

ends of pins 20.

Back to Top