TM-9-1240-401-34-P - Page 330 of 590

TM 9-1240-401-34&P

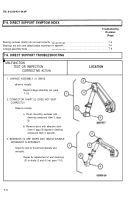

7-10. LINKAGE ASSEMBLY MAINTENANCE INSTRUCTIONS - continued

b. Repair

1 Remove corrosion, grease, and dirt from all parts.

Refer to TM 9-254 for cleaning instructions.

2 Visually inspect for missing or damaged parts.

3 Repair or replace parts in accordance with author-

ized parts listed in appendix D.

c. Assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Apply grease to bearing seat of connector (16).

Install bearing (19) and retaining ring (18) on shaft

(20).

Install bearing (19), retaining ring (18), and shaft

(20) as a unit in connector (16).

Install threaded ring (17) using adjustable spanner

wrench.

Install setscrew (15), new Iockwasher (14), and cap

screw (13) on connector (16).

Install bearing (12) in link (9), then install two

washer bearings (11) with raised portion positioned

against bearing (12).

Install link (9) in arm (8) with the bevel of the link

parallel to the bevel of the arm.

Apply grease to shouldered shaft (7).

Install shouldered shaft (7) in arm (8) and tap into

position.

Install two gripspring sets (10) with the flat sides of

the external springs positioned against washer

bearings (11).

Install two new self-locking nuts (6) on shouldered

shaft (7).

Install two gripspring sets (5) in arm (8) with the flat

sides of the external halves together.

Place plate (4) on arm (8) and plate (3) on the op-

posite side of arm (8) as shown.

Install four new Iockwashers (2) and four cap

screws (1).

7-6

Back to Top