TM-9-1240-401-34-P - Page 328 of 590

TM 9-1240-401-34&P

Troubleshooting

Procedure

(Page)

7-8. DIRECT SUPPORT SYMPTOM INDEX

Bearing surfaces (shafts) do not seat correctly .

Bearings are worn and objectionable movement

Linkage assembly binds . . . . . . . . . . . . . . . . . .

is apparent

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 7-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 7-4

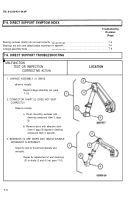

7-9. DIRECT SUPPORT TROUBLESHOOTING

LOCATION

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. LINKAGE ASSEMBLY (1) BINDS.

observe visually.

Repair linkage assembly (ref. para

7-10).

2. CONNECTOR SHAFT (2) DOES NOT SEAT

CORRECTLY.

Observe visually.

a. Clean mounting surfaces with

cleaning compound (item 3, appx

B).

b. Remove burrs with abrasive cloth

(item 4, appx B) dipped in cleaning

compound (item 3, appx B).

3. BEARINGS (3) ARE WORN AND OBJECTIONABLE

MOVEMENT IS APPARENT.

Check by feel for movement laterally and

vertically.

Repair by replacement of worn bearings

(3) or shafts (2 and 4) (ref. para 7-10).

7-4

Back to Top