TM-9-2320-272-23-2 - Page 345 of 1417

Table

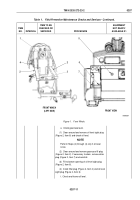

1.

Field Preventive Maintenance Checks and Services - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

13

Semiannual

Front Winch

a.

Inspect winch for security of mounting, loose or

missing mounting bolts, and broken or missing parts.

WARNING

•

Wire rope can become frayed or contain

broken wires. Wear heavy leather-

palmed work gloves when handling wire

rope. Frayed or broken wires can injure

hands. Failure to comply may result in

injury or death to personnel.

•

Never let moving wire rope slide through

hands, even when wearing gloves. A

broken wire could cut through glove and

cut hand. Failure to comply may result in

injury or death to personnel.

b.

Unwind entire cable, soak and clean with oil,

and inspect for kinks, frays, and wear. Refer to

TM

9-2320-272-10 for operation.

Any kinks, frays, or worn

cables.

c.

On M936/A1 vehicles, lubricate sheave bearing

(Figure 1, Item 1) swivel fitting (Figure 1, Item 3), trolley

wheel (Figure 1, Item 4), and level wind frame

(Figure

1,

Item

2) every 3,000 mi (4,800 km) or

6

months, whichever occurs first. If operation is

frequent, continuous, or under sever condition, service

weekly (Volume 5, WP

0820).

d.

Lubricate tensioner sheave pins

(Figure

1,

Item

5), vertical cable rollers

(Figure

1,

Item

6), and horizontal cable rollers

(Figure

1,

Item

7) every 3,000 mi (4,800 km) or

6

months, whichever occurs first. If operation is

frequent, continuous, or under sever condition, service

weekly (Volume 5, WP

0820).

TM 9-2320-272-23-2

0207

0207-10

Back to Top