TM-9-2320-272-23-2 - Page 352 of 1417

Table

1.

Field Preventive Maintenance Checks and Services - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

cause them to pop off. Replace any damaged wheel

(Volume 3, WP

0485).

b.

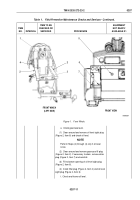

On M939/A1/A2 series vehicles, inspect wheels

(Figure 3, Item 2) for loose or missing rim nuts

(Figure

3,

Item

3). Tighten rim nuts (Figure 3, Item 3)

210 to 240 lb-ft (285 to 325 N·m). Replace any wheel

(Figure

3,

Item

2) that is broken or has stripped

threads .

c.

Inspect axle drive companion flange for oil leaks.

If oil appears to be leaking from expansion plug

(Figure

3,

Item

4) on axle drive companion flange

(Figure

3,

Item

5), notify your supervisor.

M939

M939A1/A2

1

2

3

4

5

I00003DAA

Figure 3.

Wheel Assembly.

CAUTION

On M939A2 series vehicles, use care not to

damage CTIS air seals when removing axle

components. Failure to do so may result in

further damage to axle and wheel bearings,

in addition to improper operation of CTIS sys-

tem.

NOTE

Lugnuts on left side have left-handed threads

and can be identified by an L, while lugnuts

on right side have right-hand threads, and

can be identified by an R.

d.

Clean, inspect, and lubricate axle shaft and

universal joints (Volume 3, WP

0411).

TM 9-2320-272-23-2

0207

0207-17

Back to Top