TM-9-2320-272-23-2 - Page 350 of 1417

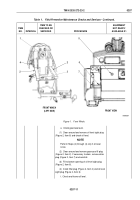

Table

1.

Field Preventive Maintenance Checks and Services - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

c.

Ensure front emergency shutoff valve is closed

and emergency and service air dummy couplings are

securely fastened (TM 9-2320-272-10).

18

Semiannual

Frame and

Crossmembers

NOTE

Inspection of crossmembers, bolts, and rivets

will be accomplished over complete vehicle.

Tighten, repair, and/or replace components

of these compressed air systems as re-

quired. If maintenance is required at a higher

level, records should reflect closest point of

reference to ensure proper identification of

components requiring service.

Inspect crossmembers for missing rivets, screws,

obstructions to other components and breaks

(TB

9-2300-247-40).

Screws or rivets loose or

missing.

(1)

Using a 0.001 in. feeler gauge, check for space

between rivet head and the riveted frame members.

Penetration of the feeler gauge between the rivet head

and riveted member is reason to suspect the riveted

connection and/or rivet should be replaced.

(2)

Thoroughly clean, grease, and oil rivet. Using

an oil can, apply lubricating oil around the connection.

Allow approximately 10 to 20 seconds for oil to

penetrate. Wipe rivet and riveted connection free of oil.

Tap rivet with an 8-pound hammer. Any indication of oil

around the rivet indicates a loose rivet. Replace all loose

rivets (TB 9-2300-247-40). Check all riveted connections

for signs of movement, such as bare or shiny spots or

other indications of movement between rivet and frame.

If movement is indicated, rivet and connection are loose.

TM 9-2320-272-23-2

0207

0207-15

Back to Top