TM-9-2320-272-23-2 - Page 349 of 1417

Table

1.

Field Preventive Maintenance Checks and Services - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

14

Semiannual

Hood

a.

Inspect hood support bar and locking pins for

condition and security of mounting. If support bar or

locking pins are defective, repair or replace as required

(Volume 4, WP

0559).

b.

Inspect hood stop cables for condition and

security of mounting. If stop cables are defective, repair

or replace as required (Volume 4, WP

0560).

c.

Lubricate hood trunnion every 6,000 mi

(9,656

km) or 6 months, whichever occurs first (Volume

5, WP

0820).

d.

Lubricate hood hinges every 1,000 mi

(1,600

km) or monthly, whichever occurs first (Volume

5, WP

0820).

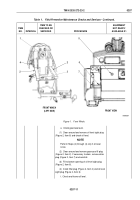

15

Semiannual

Front Lights and

Cable Assembly

Inspect front light cable assembly wiring for frays, splits,

missing or damaged insulation, or poor connections.

Repair affected wiring (Volume 3, WP

0352).

16

Semiannual

Motor Mount

Trunnions

a.

Check two front engine mounting trunnion

screws for tightness. If engine mounting trunnion screws

are loose, tighten.

b.

Tighten five lower trunnion mount screws

65

to

75

lb-ft

(88 to 102 N·m).

c.

On M939A2 series vehicles, check front

mounting locknuts for tightness. Tighten mounting

locknuts 75 to 85 lb-ft (102 to 115 N·m).

17

Semiannual

Emergency and

Service

Compressed Air

Systems

a.

Inspect front emergency and service air and

dummy couplings for serviceability and seals.

NOTE

Inspection of emergency and service air lines

and fittings will be accomplished over com-

plete vehicle. Tighten, repair, and/or replace

components of these compressed air sys-

tems as required. If maintenance is required

at a higher level, records should reflect clos-

est point of reference to ensure proper iden-

tification of components requiring service.

b.

Inspect air lines, fittings, and emergency shutoff

valve for security of mounting, tightness of connections,

and damage that could cause air leaks (Volume 5,

WP

0819).

TM 9-2320-272-23-2

0207

0207-14

Back to Top