TM-9-2320-272-23-2 - Page 634 of 1417

CLEANING AND INSPECTION

WARNING

Solvent cleaning compound is flammable and toxic. Do not use near an open flame and

always have a fire extinguisher nearby when solvents are used. Use only in well-ventilated

places, wear protective clothing, and dispose of cleaning rags in approved container. Failure

to comply may result in damage to equipment, injury, or death to personnel.

NOTE

To prevent hardening and drying of foreign substances, clean cooler element as soon as

possible after removal.

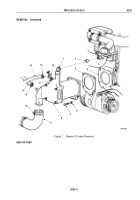

1.

Clean cooler housing (Figure 3, Item 1) with solvent cleaning compound and inspect for cracks and stripped

threads. Replace cooler housing if cracked or threads are stripped.

2.

Soak and flush oil cooler element (Figure 3, Item 2) with solvent cleaning compound and inspect for broken

and cracked welds. Replace cooler element if broken or cracked.

WARNING

Eyeshields must be worn when cleaning with compressed air. Compressed air source will

not exceed 30 psi (207 kPa). Failure to comply may result in injury or death to personnel.

3.

Immerse oil cooler element (Figure 3, Item 2) in water, apply 30 psi (207 kPa) air pressure, and plug opposite

end. Replace oil cooler element if air bubbles are observed.

1

2

M9338DAA

Figure 3.

Engine Oil Cooler Cleaning and Inspection.

END OF TASK

TM 9-2320-272-23-2

0233

0233-5

Back to Top