TM-9-2320-272-23-5 - Page 342 of 623

INSTALLATION

1.

For General Cleaning Instructions, refer to (WP

0819).

2.

For General Inspection Instructions, refer to (WP

0819).

3.

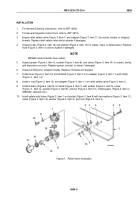

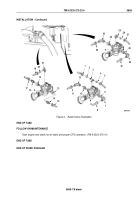

Inspect relief safety valve (Figure 3, Item 1) and adapter (Figure 3, Item 11) for cracks, breaks, or stripped

threads. Replace relief safety valve and/or adapter if damaged.

4.

Inspect hoses (Figure 3, Item 12) and duckbill (Figure 3, Item 13) for cracks, tears, or deterioration. Replace

hose (Figure 3, Item 12) and/or duckbill if damaged.

NOTE

M936A2 model vehicles have spacer.

5.

Inspect spacer (Figure 3, Item 4), bracket (Figure 3, Item 8), and clamp (Figure 3, Item 14) for cracks, bends,

and excessive corrosion. Replace spacer, bracket, or clamp if damaged.

6.

Inspect all fittings for stripped threads. Replace if threads are stripped.

7.

Install hose (Figure 3, Item 12) and duckbill (Figure 3, Item 13) on adapter (Figure 3, Item 11) with clamp

(Figure

3,

Item

14).

8.

Install o-ring (Figure 3, Item 15) and adapter (Figure 3, Item 11) on relief safety valve (Figure 3, Item 1).

9.

Install bracket (Figure 3, Item 8) on frame (Figure 3, Item 7) with washer (Figure 3, Item 5), screw

(Figure

3,

Item

6), washer (Figure 3, Item 9), and nut (Figure 3, Item 10). Install spacer (Figure 3, Item 4)

(M936A2

vehicles only).

10.

Install safety relief valve (Figure 3, Item 1) on bracket (Figure 3, Item 8) with two washers (Figure 3, Item 17),

screw (Figure 3, Item 16), washer (Figure 3, Item 2), and nuts (Figure 3, Item 3).

M6337DAA

16

17

3

2

4

5

6

7

13

14

12

11

10

9

8

15

1

Figure 3.

Relief Valve Installation.

TM 9-2320-272-23-5

0809

0809-5

Back to Top