TM-9-2320-272-24-2 - Page 636 of 991

TM 9-2320-272-24-2

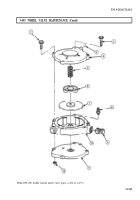

3-456. FRONT WHEEL VALVE MAINTENANCE

THIS TASK COVERS:

a. Removal

b. Cleaning and Inspection

c. Installation

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

M939A2

TM 9-2320-272-10

TOOLS

TM 9-2320-272-24P

General mechanic’s tool kit (Appendix E, Item 1)

MATERIALS/PARTS

EQUIPMENT CONDITION

●

Parking brake set (TM 9-2320-272-10).

●

Air reservoirs drained (TM 9-2320-272-10).

Three locknuts (Appendix D, Item 334)

Three lockwashers (Appendix D, Item 400)

O-ring (Appendix D, Item 437)

O-ring (Appendix D, Item 487)

Four locknuts (Appendix D, Item 273)

Antiseize tape (Appendix C, Item 72)

GENERAL SAFETY INSTRUCTIONS

Eyeshields must be worn when releasing

compressed air.

a. Removal

1.

2.

3.

4.

5.

6.

7.

8.

WARNING

Air system components are subject to high pressure. Always relieve

pressure before loosening or removing air system components.

Remove cap (2) and valve stem (3) from tank valve (5), and allow tire (18) to deflate completely.

Install valve stem (3) and cap (2) on tank valve (5).

Remove two locknuts (27), washers (26), screws (28), washers (29), shield (1), and spacer (25) from

studs (16) and axle flange (20). Discard locknuts (27).

Remove hose (15) from elbow (7) and turret valve (17).

Loosen nut (14) and remove air manifold (22) from wheel valve (4).

Remove screw (24), washer (23), air manifold (22), and O-ring (21) from axle flange (20) and air

tube (19). Discard O-ring (21).

Remove two locknuts (8), washers (9), washers (10), and wheel valve (4) from studs (16). Discard

locknuts (8).

Remove three locknuts (13), lockwashers (12), and bracket (11) from wheel valve (4). Discard

locknuts (13) and lockwashers (12).

Remove elbow (7) and O-ring (6) from wheel valve (4). Discard O-ring (6).

NOTE

For repair of wheel valves, refer to para. 3-461.

b. Cleaning and Inspection

1.

For general cleaning instructions, refer to para. 2-14.

2.

For general inspection instructions, refer to para. 2-15.

3.

Inspect wheel valve (4) for cracks, leaks, and stripped threads. Replace or repair wheel valve (4) if

cracked, leaking, or threads are stripped.

4.

Inspect bracket (11), shield (1), air manifold (22), hose (15), spacer (25), elbow (7), and turret

valve (17) for cracks, bends, or stripped threads. Replace parts if damaged.

3-1244

Back to Top