TM-9-2320-272-24-3 - Page 682 of 799

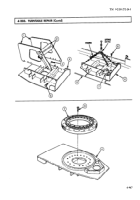

4-203. TURNTABLE

TM 9-2320-272-24-3

THIS TASK COVERS:

a. Removal

b. Disassembly

c. Cleaning, Inspection, and Repair

d. Assembly

e. Installation

INITIAL SETUP:

APPLICABLE MODELS

M936/A1/A2

Tools

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 145)

Lifting device

Chains

MATERIALS/PARTS

Eighteen locknuts (Appendix D, Item 316)

Drycleaning solvent (Appendix C, Item 71)

REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

TM 9-237

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-272-10).

Hydraulic oil reservoir removed (para. 4-188).

Boom elevating cylinders removed (para. 4-1931.

Hydraulic swivel valve removed (para. 4-198).

Crane swinger gearcase removed (para. 4-200).

Gondola removed (para. 4-202).

GENERAL SAFETY INSTRUCTIONS

All personnel must stand clear during lifting

operations.

Keep fire extinguisher nearby when using

drycleaning solvent.

Drycleaning solvent is flammable and toxic. Do

not use near an open flame.

WARNING

All personnel must stand clear during lifting operations. A

snapped cable, or shifting or swinging load, may cause injury to

personnel.

1.

Remove eighteen locknuts (3), screws (5), two turntable side plates (1), and crossover tubes (2) from

turntable base plate (4). Discard locknuts (3).

2.

Remove eighteen screws (6) from turntable gear and bearing (7) and crane body (8) by rotating

turntable base plate (4) so access hole exposes each screw (6).

NOTE

Assistant will help with steps 3 and 4.

3.

Attach two utility chains to turntable base plate (4).

4.

Attach lifting device to chains and lift turntable base plate (4) away from crane body (8).

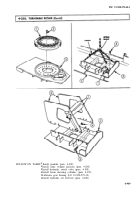

5.

Remove two utility chains and lifting device from turntable base plate (4).

Remove eighteen screws (9) and turntable gear and bearing assembly (7) from underside of turntable

base plate (4).

4-946

Back to Top