TM-9-2320-272-24-3 - Page 686 of 799

4-204. BOOM

TM 9-2320-272-24-3

THIS TASK COVERS:

a. Disassembly

b. Cleaning, Inspection, and Repair

INITIAL SETUP:

c. Assembly

d. Vertical Adjustment

APPLICABLE MODELS

M936/A1/A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Arbor press

Mandrel

MATERIALS/PARTS

Cotter pins (Appendix D, Item 68)

Cotter pin (Appendix D, Item 77)

Two locknuts (Appendix D, Item 311)

Twenty-four lockwashers (Appendix D, Item 377)

GAA grease (Appendix C, Item 28)

Drycleaning solvent (Appendix C, Item 71)

REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-24P

TM 9-237

EQUIPMENT CONDITION

Hoist winch removed (para. 4-192).

Inner boom removed (para. 4-195).

Extension cylinder removed (para. 4-196).

Boom rollers removed (para. 4-197).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

Drycleaning solvent is flammable and toxic. Do

not use near an open flame.

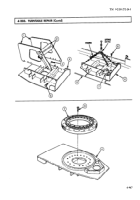

1.

Remove cotter pin (10), crane sheave pin (13), and crane sheave (12) from outer boom (14). Discard

cotter pin (10).

2.

With arbor press and mandrel, remove two bearings (11) from crane sheave (12)

3.

Remove two locknuts (5), screws (17), and spacers (4) from inner boom (9). Discard locknuts (5).

4.

Remove cotter pin (6), cable sheave pin (15), and two cable sheaves (1) from inner boom (9). Discard

cotter pin (6).

5.

Using arbor press and mandrel, remove two sheave bushings (2), thrust washers (3), and spacer (18)

from two cable sheaves (1).

6.

Remove one hundred and four screws (7) and four boom tracks (8) from inner boom (9).

7.

Remove grease fitting (16) from cable sheave pin (15).

WARNING

Drycleaning solvent is flammable and toxic. Do not use near open

flame and always have a fire extinguisher nearby when solvents

are used. Use only in well-ventilated places, wear protective

clothing, and dispose of cleaning rags in approved container.

Failure to do this may result in injury or death to personnel and/or

damage to equipment.

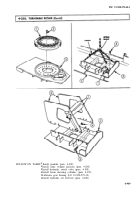

1.

Clean all boom components with drycleaning solvent.

2.

Inspect inner boom (9) and outer boom (14) for bends and cracked or broken welds. If welds are

cracked or broken, refer to TM 9-237. If bent, replace.

3.

Inspect four boom tracks (8) for cracks, breaks, and bends. Replace if cracked, bent, or broken.

4.

Inspect cable sheave pins (13) and (15) for breaks or out-of-round condition. Replace if broken or

out-of-round.

4-950

Back to Top