TM-9-2320-272-24-3 - Page 684 of 799

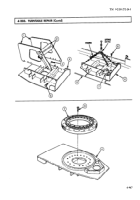

4-203. TURNTABLE

TM 9-2320-272-24-3

WARNING

Drycleaning solvent is flammable and toxic. Do not use near open

flame and always have a fire extinguisher nearby when solvents

are used. Use only in well-ventilated places, wear protective

clothing, and dispose of cleaning rags in approved container.

Failure to do this may result in injury to personnel and/or damage

to equipment.

1.

Clean turntable base plate (3) and gear and bearing assembly (1) with drycleaning solvent.

2.

Inspect turntable base plate (3) for cracks and breaks. If cracked or broken, refer to TM 9-237.

3.

Inspect turntable gear and bearing assembly (1) for cracks, pits, scores, and broken teeth. If cracked,

pitted, scored, or broken teeth are evident, replace turntable gear and bearing assembly (1).

Install turntable gear and bearing assembly (1) on underside of turntable base plate (3) with eighteen

screws (2). Tighten screws (2) 170-200 lb-ft (231-271 N•m).

1.

2.

3.

4.

5.

WARNING

All personnel must stand clear during lifting operations. A

snapped cable, or shifting or swinging load, may cause injury to

personnel.

NOTE

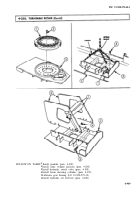

Assistant will help with steps 1 and 2.

Attach two utility chains to turntable base plate (3).

Attach lifting device to two utility chains and lift turntable base plate (3) onto crane body (5).

Remove two utility chains and hoist hook from turntable base plate (3).

Rotate turntable base plate (3) on gear bearing assembly (1) to expose each screw hole in turntable

base plate (3) and install on crane body (5) with eighteen screws (4). Tighten screws (4) 170-200 lb-ft

(231-271 N•m).

Install turntable side plates (6) and crossover tubes (7) on turntable base plate (3) with eighteen

screws (9) and new locknuts (8). Tighten screws (9) 170-200 lb-ft (231-271 N•m).

4-948

Back to Top