TM-9-2320-273-34 - Page 227 of 801

TM 9-2320-273-34

(3)

Install an air hose with an air pressure gage 0-100 psi (0-690 kPa) and connect in the

1/8-in. NPT hole for test of output clutch (5).

(4)

Start and run the engine. When the vehicle air system pressure is normal (120 psi -830 kPa)

push in the knob of the air valve on the ratio selector.

(5)

Put the system park brake ON to prevent vehicle from rolling.

-

(6)

With the vehicle air system at normal operating pressure, move the selector lever to the

16th speed position.

Record the air pressure reading from the test gage. Move the selector lever to the

12th speed position and record the test gage reading. Move the selector lever to the 8th speed position

and record the test gage reading. Move the selector lever to the 4th speed position and record the test gage

reading. Stop engine and pull out on the knob on the ratio selector.

(7)

Compare readings with correct settings shown in table 7-1. If any of the pressure readings

are not correct, the pressure regulator must be adjusted.

Table 7-1. Air Pressure to Engage Output Clutch.

l

SPEEDS

PSl

kPa

13th through 16th

22+5 or -2

150+35 or -14

9th through 12th

40+5 or -2

280+ 35 or -14

5th through 8th

77+5 or -2

530+ 35 or -14

1st through 4th

90+5 or -2

620+ 35 or -14

l

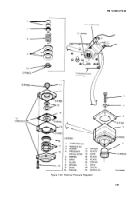

b. Pressure Regulator Shims.

Figure 7-48 shows the location of shims that will require changing if

any of the test readings were not correct. Shims come in only two thicknesses, .010 in. (0.25 mm) or .030

in. (0.76 mm). The .010 in (0.25 mm) shim changes pressure setting 1 psi (7 kPa). The .030 in (0.76 mm)

shim changes pressure setting 3 psi (20 kPa). Shim locations that control the pressure settings, shown

in table 7-1, are as follows:

{1)

Location (6) controls the pressure settings for the 9th thru 12th ratio position.

(2)

Location (9) controls the pressure settings for the 13th thru 16th ratio position.

NOTE

These shims also control a uniform

increase or decrease in pressure at the

four test points.

(3)

Location (13) controls the pressure setting for the 5th thru 8th ratio position.

(4)

Location (17) controls the pressure setting for the 1st thru 4th ratio position.

c. Pressure Regulator Adjustment.

Find the thickness of shims required and their location before

any removal and disassembly of the pressure regulator is made. Determine shim changes as follows:

(1)

If the test pressure readings are either all too high or too low shims (9, fig. 7-48) must be

changed. To increase pressure add shims, to decrease pressure remove shims.

7-49

Back to Top