TM-9-2320-273-34 - Page 432 of 801

TM 9-2320-273-34

(9)

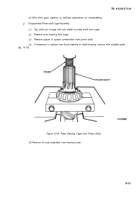

Check for the following pressure and torque for pinion bearing preload:

a.

Pressure to obtain correct preload: 11 tons

b.

Nut torque to obtain correct preload:

1000-1300 Ib-ft (1356-1763 N·m)

2

(10)

If rotating torque is not within 5-25 lb-in. for new bearings or 5-15 lb-in. for reused

bearings, use thinner spacer to increase or thicker spacer to decrease preload.

Example:

Assuming pinion cage diameter to be 6 in., the radius would be 3 in. and

with 5 Ibs pull would equal 15 lb-in. preload torque.

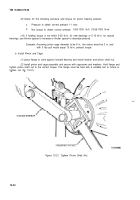

b. Install Pinion and Cage.

(1) press

flange or yoke against forward bearing and install washer and pinion shaft nut.

(2)

Install pinion and cage assembly and secure with capscrews and washers. Hold flange and

tighten pinion shaft nut to the correct torque. The flange must be held with a suitable tool or fixture to

tighten nut (fig. 10-21).

Figure 10-21. Tighten Pinion Shaft Nut.

10-24

Back to Top