TM-9-2320-273-34 - Page 439 of 801

TM 9-2320-273-34

(4)

T

O

secure the correct adjustment of 0.010-0.015 in. clearance, loosen thrust screw 1/4

turn and lock securely with nut. Torque nut 40-55 Ib-ft (54-75 N·m).

(5)

Recheck clearance between end of thrust screw and backface of gear for 0.010-0.015 in.

(0.254-0,381 mm) clearance.

Figure 10-29. Adjust Drive Gear Thrust Screw.

10-8.

Differential Carrier Installation.

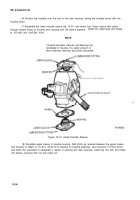

a. Clean and Inspect the Housing.

WARNIN G

Compressed air used for cleaning purposes

will not exceed 30 psi. Use only with effec-

tive chip guarding and personal protective

equipment (goggles/shield, gloves, etc.).

(1)

Remove any accumulation of dirt, grit or gum from the housing bowl and sleeves. Clean

the housing thoroughly with dry cleaning solvent (item 12, App B) and blow dry with compressed air.

(2)

Inspect the housing for cracks, nicks and burrs at machined surfaces. Remove nicks and

burrs with a stone or file. Make all necessary repairs or parts replacement before installing the drive unit

in housing. Be sure the housing is thoroughly cleaned after repairing.

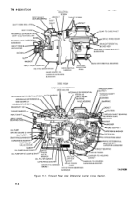

b. Install the Differential Carrier.

(1)

Apply silicone sealant material (item 24, App B) over the drive unit opening in the housing.

Driving carrier into the housing with a steel

hammer will damage the carrier flange and

cause severe oil leakage.

10-31

CAUTIO N

Back to Top