TM-9-2320-273-34 - Page 444 of 801

TM 9-2320-273-34

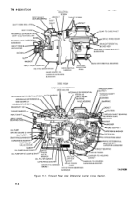

(2)

Install two assembly studs to act as dowels into knuckle 180° apart. Tighten studs

finger tight.

(3)

Install spindle into knuckle pilot by slipping over assembly studs. Spindle should be in-

stalled so that wheel bearing adjusting nut keyway slot is pointed up (approximately 1 o’clock on left

side of vehicle; 11 o’clock on right side).

(4)

Install a suitable band around brake shoes during reassembly to the brake. Remove brake

shoe return springs.

(5)

Install brake assembly and oil slinger over assembly studs. Secure all parts with capscrews

and washers. Assembly studs may be removed after two capscrews are installed. Torque capscrews to

180-230 Ib-ft (244-312 N·m).

(6)

Reinstall both brake shoe return springs using return spring pliers.

e. Reassemble Wheel Bearing and Studs into Hub.

Before pressing the wheel studs into

position, also make sure stud serrations

in corresponding holes in drum and

serrations of studs aline correctly. If

this procedure is not followed a larger

stud hole will develop, resulting in

loose wheel studs.

(1)

If wheel studs were removed during disassembly, place hub in a press with the inner (long)

end pointing upward. Aline wheel studs in hub holes and press into position. If a press is not available,

a brass hammer or drift may be used to seat wheel studs. Do not strike studs with a steel hammer.

(2)

If wheel bearings were removed from the hub, reassemble inner and outer bearing cups

into hub using a press and suitable sleeve.

(3)

Before assembling hub onto the spindle, repack bearing cones and hub cavity with grease

even with the inside diameter of the bearing caps.

Do not use excessive pressure to install

seal or tap seal after it has bottomed.

This will crush the seal retainer and

seal damage will result.

(4)

Place the inner bearing cone in position inside the hub against its cup, and install new

hub and spindle oil seal. Coat outer diameter of seal retainer with Permatex or equal and tap into

position until seal bottoms in bore.

(5)

Reassembly of outer bearing cone into hub is accomplished when hub is assembled onto

wheel spindle.

10-36

CAUTIO N

CAUTIO N

Back to Top