TM-9-2320-273-34 - Page 443 of 801

TM 9-2320-273-34

c. Adjust Knuckle Bearing Preload.

NOTE

to the wire or

pilot diameter

the scale.

To achieve an accurate bearing preload

reading, do not assemble the vehicle

steering arm ball stud or the cross tube

(tie-rod) assembly to knuckle at this

time. Use rotating torque, not starting

torque.

(1)

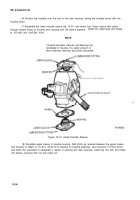

Wrap soft wire or cord around the tie-rod ball stud boss and attach a common pound scale

cord. While holding the outer shaft of the universal joint away from the spindle-to-knuckle

, rotate the knuckle with the pound scale (fig. 10-32). Note the pounds pull indicated on

Figure 10-32. Measure Knuckle Rotating Torque.

(2)

To achieve correct knuckle bearing preload of 11-15 Ib-ft (15-20 N·m) rotating torque, the

pounds pull indicated on the scale should fall between 15 and 21 Ibs.

a.

If the pounds pulled on scale in step

(1)

is within the 15 Ibs minimum and 21 Ibs

maximum (7-10 kg) shimming between the knuckle and sleeve and bearing preload

is correct.

b.

To increase bearing preload, increase pounds pulled on scale by removing shims.

c.

To decrease bearing preload, decrease pounds pulled on scale by adding shims.

(3)

If it is necessary to readjust the thickness of shims for correct knuckle bearing preload,

disassemble the upper knuckle sleeve; then repeat step

(8)

in paragraph 10-9

b

and steps

(1)

and

(2)

of

the paragraph above.

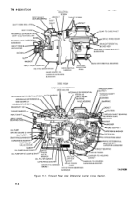

d. Reassemble Spindle, Brake Assembly, and Oil Slinger.

(1)

If felt seal and retainer assembly, oil seal wiper, and thrust washer have been removed from

inside spindle, install these parts.

10-35

Back to Top