TM-9-2320-273-34 - Page 433 of 801

TM 9-2320-273-34

(3)

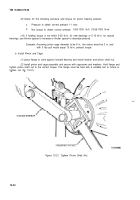

Recheck pinion bearing preload torque.

If rotating torque is not within 5-25 lb-in. for new

bearings or 5-15 lb-in. for reused bearings, repeat the foregoing procedure.

(4)

Hold yoke and remove pinion shaft nut and yoke.

(5)

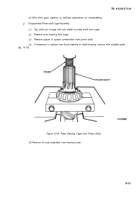

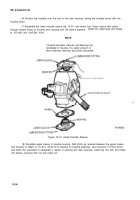

Lubricate pinion shaft oil seal and cover outer edge of seal body with silicone sealant

(item 24, App B) Compound. Press seal against cover shoulder with seal driver (fig. 10-22).

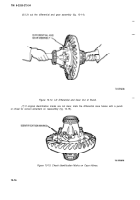

Figure 10-22. Install Oil Seal.

(6)

Install a new gasket and bearing cover.

(7) InstalI

yoke as described in TM 9-2320-273-20,

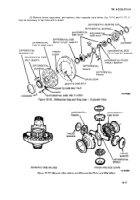

c. Assemble the Differential and Gear.

The gear should not be pressed or driven

on the case, as this would cause excessive

metal particles to lodge between the gear

and case, thus resulting in gear run-out.

Proper installation should, therefore,

incorporate preheating the gear to assure

correct interference fit and to eliminate

metal pickup.

(1)

Heat the ring gear in oil to approximately 160°F-180°F for about ten minutes before

assembly.

(2)

Install fourteen bolts, washers, and nuts. Torque to 180-230 Ib-ft (244-312 N·m).

(3)

Pre-lubricate the differential case inner walls and all component parts with the recommended

axle lubricant.

(4)

Position the thrust washer and side gear in the gear case half.

(5)

Place the spider with pinions and thrust washers in position.

10-25

CAUTIO N

Back to Top