TM-9-2320-273-34 - Page 434 of 801

TM 9-2320-273-34

(6)

Install the second side gear and thrust washer.

(7)

Position the other case half over the assembly, alining match marks of both halves. Draw

—

the assembly together with three equally spaced capscrews.

(8)

Install the remaining capscrews and torque to 85-115 Ib-ft(115-156 N·m).

(9)

If new bearings are to be used, press squarely and firmly on the differential case halves with

a suitable sleeve.

d. Rolling Resistance of Differential Nest.

(1)

Place the differential and ring gear assembly in a vise with soft metal jaws.

(2)

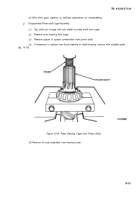

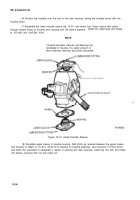

Insert a checking tool (made from a splined axle shaft end) into the differential nest

(fig.

10-23).

Allow the splines of the tool to engage with the spline of one side gear only.

Figure 10-23. Install Checking Tool.

(3)

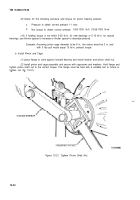

Using a suitable socket and torque wrench, rotate the differential nest while observing the

scale on the torque wrench (fig. 10-24). Correct rolling resistance of the differential assembly is 50 Ib-ft

(68 N·m) torque maximum applied to one side gear.

Figure 10-24. Check Rolling Resistance.

10-26

Back to Top