TM-9-2320-273-34 - Page 589 of 801

TM9-2320-273-34

b.

Inside every hub are two brake shoes and four brake linings. One of the linings on each shoe

may be different from the other.

Make sure you use the specified linings for the

brake shoes you are servicing. Ensure that the lin-

ing is installed in the correct position on the proper

shoe. Stopping effectiveness is directly affected by

the lining position.

Whenever you reline brake shoes, reline all the

shoes on an axle. Failure to do so will cause un-

even braking and pulling to one side.

NOTE

In this manual, the phrase shoe and lining assembly

means one brake shoe, two linings, and the rivets

holding the linings to the shoe.

A brake lining kit, in this manual, is a set of brake

linings and rivets sufficient to repair all the brake

shoes on one axle, that is, eight linings and more

than enough rivets to attach the linings to the shoes.

Clamp shoe in a vise and drill out the old rivets, then remove the linings. Use a drill bit no

Iarger in diameter than the rivet. Clean the shoe before clamping new lining in position. Use only the

rivets that come in the brake lining kit.

Make certain the lining is firmly clamped to the shoe,

locating the C-clamp as close to the rivet holes as

possible.

d.

Clamp the lining to the brake shoe with C-clamps so the rivet holes in both pieces are in

alinement.

e.

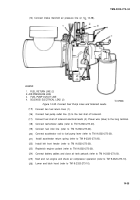

Drive the new rivets squarely into the holes with a 7/16 inch flat head drift.

f.

Form the rivets with

14-44 (work from heel to toe).

the correct tubular rivet set following the sequence

shown in figure

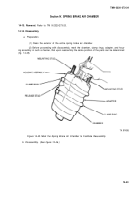

Figure 14-44. Rivet Forming Sequence.

14-42

TA 075567

CAUTIO N

CAUTIO N

Back to Top