TM-9-2330-227-14-P - Page 314 of 576

5-40

TM 9-2330-227-14&P

Section IV. BRAKE MAINTENANCE

Page

Page

Airbrake Chamber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-44

Brakeshoe Assembly Repair,

Brakeshoe Assembly Repair, One-

Two-Cylinder Brake Assembly . . . . . . . . . . . . . . . . 5-40

Cylinder Brake Assembly Option . . . . . . . . . . . . . . 5-42

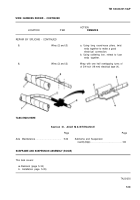

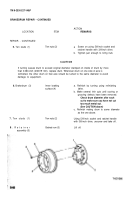

BRAKESHOE ASSEMBLY REPAIR, TWO-CYLINDER BRAKE ASSEMBLY

This task covers:

Repair (page 5-40)

INITIAL SETUP

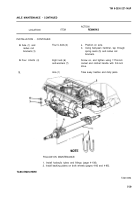

Tools

Materials/Parts - Continued

Brush, wire

Solvent, drycleaning, PD-680

Gage, depth

(item 18, appendix E)

Gage, thickness 0.002-inch (0.051-mm)

Reliner, brake

Personnel Required

Materials/Parts

One

Mask, protective

Equipment Condition

Rivets (16 required)

Shim stock, as required

Brakeshoes removed (page 4-84).

ACTION

LOCATION

ITEM

REMARKS

WARNIN G

Drycleaning solvent PD-680 is both toxic and flammable. Avoid prolonged breathing of

vapors and avoid skin contact. Use only in well-ventilated area, and keep away from

open flame. Injury to personnel could occur.

Brake linings contain asbestos fibers. Protective mask must be worn while performing

maintenance on brake linings. Failure to do so could result in serious injury to

personnel.

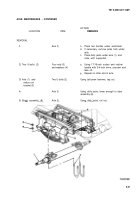

Worn brake linings could result in injury or death to personnel. When brake linings are

worn to within 0.0625-inch (1.59 mm) of rivets, they must be replaced.

NOT E

There are four brakeshoes on the semitrailer. This procedure is for one. Repeat for

the others.

Back to Top