TM-9-2330-227-14-P - Page 306 of 576

5-32

TM 9-2330-227-14&P

WIRE HARNESS REPAIR - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

WARNIN G

Contact with live 110-volt electric wires could result in serious injury or death. Make

sure power source is disconnected before performing maintenance on the electrical

system.

NOT E

For connector repair, see page 5-8.

REPAIR BY SPLICING

1.

2.

3.

4.

Harness (1)

Wire (2)

Using diagonal cutting pliers, cut off

damaged portion of wire (2).

New wire (3)

Using diagonal cutting pliers, cut new

wire of same gage and type as wire being

replaced to desired length.

If necessary install connector on new

wire (page 4-71).

Wires (2) and (3)

Using wire stripper, strip insulation

3/4-inch (19 mm) from the end of each

wire.

WARNIN G

Drycleaning solvent PD-680 is both toxic and flammable. Avoid prolonged breathing of

vapors, and avoid skin contact. Use only in well-ventilated area, and keep away from

open flame or excessive heat. Injury to personnel could occur.

NOT E

Make sure wire ends are clean before soldering. If necessary, clean with cleaning

solvent and stiff fiber brush. Solder must be non-acid type; use rosin flux. Wires

and soldering iron must be pre-tinned for good connection and maximum transfer of

heat. Clean all solder joints with an acid swabbing brush and alcohol after soldering to

get a bright, clean surface.

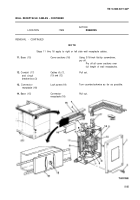

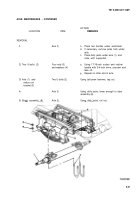

Wires (2) and (3)

Twist strands of each wire separately,

and using soldering iron, tin strands.

Back to Top