TM-9-2330-342-23-P - Page 585 of 1348

FIELD MAINTENANCE

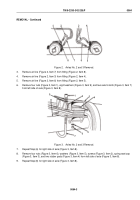

AXLE NO. 3 ALIGNMENT

INITIAL SETUP:

Tools and Special Tools

Jack, Dolly Type (WP

0194, Table 1, Item 24)

Jack, Stabilizer (2) (WP

0194, Table 1, Item 25)

Trestle (Jackstand), 7 Ton (2) (WP

0194, Table 1,

Item 15)

Plumb Bob (WP

0194, Table 1, Item 31)

Socket Set, 1 in. Drive (WP

0194, Table 1, Item

37)

Socket Set, 3/4 in. (WP

0194, Table 1, Item 35)

Tape Measure, 25 ft (WP

0194, Table 1, Item 15)

Tool Kit, General Mechanic's: Automotive

(WP

0194, Table 1, Item 47)

Wrench, Impact Electric (WP

0194, Table 1, Item

51)

Wrench, Torque, Click, Ratcheting, 3/4" Drive, 600

ft-lb (WP

0194, Table 1, Item 42)

Materials/Parts

Chalk, Marking (WP

0193, Table 1, Item 12)

Personnel Required

Wheeled Vehicle Mechanic (2)

References

Fig. 35 (WP

0170)

WP

0094

Equipment Condition

Wheels chocked (TM 9-2330-342-10). (WP

0190)

Drawbar level (TM 9-2330-342-10). (WP

0190)

ALIGNMENT

1.

Using a jack, raise rear of trailer (Figure 1, Item 1) and support on two jackstands under suspension hanger

assembly (Figure 1, Item 3) so rear wheels (Figure 1, Item 5) are off ground.

2

1

JACKSTAND

3

4

5

Figure 1.

Axle No. 3 Alignment.

2.

Remove rear wheels (Figure 1, Item 5) from Axle No. 2 (Figure 1, Item 4) and Axle No. 3 (Figure 1, Item 2)

(WP

0094).

NOTE

Center of axle spindle covers is marked with an indentation.

TM 9-2330-342-23&P

0063

0063-1

Back to Top