TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 267 of 528

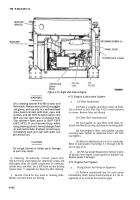

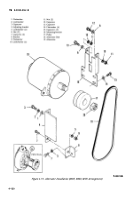

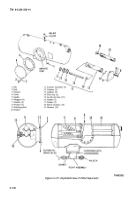

(3) Unscrew pipe plug (fig. 4-111) directly below

alternator from the intermediate housing.

(4) Remove bolt (3), lockwasher (2), and

flatwasher (1) securing alternator to adjusting bracket (4).

(5) Remove bolt (7), lockwasher (5), and nut (6),

then remove the adjusting bracket (4).

(6) Pull down on alternator to release tension on

alternator belt. Remove alternator belt from pulley.

(7) From underneath semitrailer, remove two

bolts (12 and 13), flatwashers (9), lockwashers (10), and

nuts (11).

(8) Remove ground cable (nearest) from

alternator.

(9) Pull alternator from mounting bracket (16).

Turn alternator and remove positive cable.

(10) Remove alternator.

b.

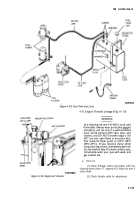

Adjustment of Alternator Drive Belt (Fig. 4-112).

(1) Loosen alternator adjusting bolt (3,

fig. 4-111) and mounting bolts (12 and 13) securing

alternator to mounting bracket (16).

(2) Insert a crowbar (fig. 4-112) between

alternator and the pump housing. Be sure that lower end

of bar will bear against the pump housing. Pull UP on the

bar and apply sufficient force to obtain proper belt

tension. Proper belt tension is

1/8 to ¼-inch deflection in

the belt midway between the two pulleys.

(3) Tighten adjusting screw (3, fig. 4-111) and two

mounting bolts (12 and 13).

TA099852

Figure 4-112. Belt Deflection Adjustment.

TM 9-2330-356-14

c.

Replacement of Alternator Pulley (Fig. 4-111).

(1)

(2)

(3)

rotor shaft.

(4)

(5)

(6)

Remove alternator (19) (para 4-78).

Clamp pulley in a soft jaw vise.

Remove shoulder nut (20) from alternator

Remove pulley (17) and key from rotor shaft.

Install new pulley in reverse order.

Install alternator (19) (step

d).

d.

Installation of Alternator (Fig. 4-111).

(1) Connect the positive cable to the positive

terminal on the alternator and the negative cable to the

negative terminal on alternator (19).

(2) Locate sliding bushing in one of ears on the

alternator. Move bushing so it is flush with the inside of

ear. This will give more clearance between the ears to

facilitate installation of alternator to the mounting

bracket (16, fig. 4-111).

(3) Install bolt (13) and washer (9) into bushing

on alternator.

(4) Install alternator over ears of mounting

bracket (16). While doing this, have a second person

replace both bolts (12 and 13) through ears of alternator

and mounting bracket. Replace washers (10) and nuts (11).

Do not tighten.

(5) Replace alternator belt (18) over pulley (17).

(6) Replace adjusting bracket (4) on alternator

with capscrew (3), lockwasher (2), and flatwasher. Do not

tighten.

(7) Secure adjusting bracket (4) to bracket (8)

with capscrew (7), lockwasher (5), and nut (6).

(8) Replace buss bar box cover and secure it with

two capscrews and nuts.

(9) Adjust alternator belt (para 4-79).

(10) Connect positive and negative battery cables

to battery.

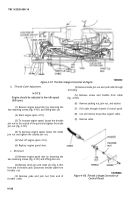

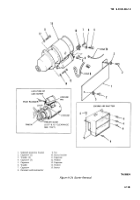

Replacement of Alternator Drive Belt (M967A1,

M969A1, and M970A1) (Figs. 4-113

through 4-122).

(1) Remove any broken belt fragments from the

drive area. Remove the capscrews and lockwashers

securing the flexible element drive ring (fig. 4-113).

4-131

Back to Top